Aangepaste Droëfilmkondensators-ontwerp vir hoëfrekwensie-kragelektronika

Ons sterkpunte

1. CRE doen voortdurend die ontwikkeling om energiedigtheid, betroubaarheid en doeltreffendheid te verhoog terwyl grootte, gewig en koste verminder word.

2. As 'n professionele ontwerper van filmkondensators, pas ons film-/gesegmenteerde filmmateriale en -tegnieke toe om die kapasitor se werkverrigtingseienskappe vir 'n gegewe toepassing te optimaliseer.

3. Met jare se ondervinding hou CRE aan om innoverende kondensatoroplossings vir ons kliënte regoor die wêreld te ontwikkel.

Tegniese data

| Bedryfstemperatuurreeks | Maksimum bedryfstemperatuur: + 70 ℃ Boonste kategorie temperatuur: +60 ℃ Laer kategorie temperatuur: -40 ℃ | |

| kapasitansiebereik | 100μF~20000μF | |

| On/ Nominale spanning On | 600V.GS~4000V.GS | |

| Kapasitansie-toleransie | ±5%(J);±10%(K) | |

| Weerstaan spanning | Vt-t | 1.5Un GS/60S |

| Vt-c | 1000+2×Un/√2(V.AC)60S (min 3000 V. WS) | |

| Oorspanning | 1.1Un(30% van aan-lading-gedurende) | |

| 1.15Un(30min/dag) | ||

| 1.2Un(5min/dag) | ||

| 1.3Un(1min/dag) | ||

| 1.5Un (100ms elke keer, 1000 keer gedurende die leeftyd) | ||

| Dissipasiefaktor | tgδ≤0.003 f=100Hz | |

| tgδ0≤0.0002 | ||

| Engels as tweede taal (ESL) | <150 NH | |

| Vlamvertraging | UL94V-0 | |

| Maksimum hoogte | 2000m | |

| Wanneer die hoogte bo 2000m tot onder 5000m is, is dit nodig om die gebruik van 'n verminderde hoeveelheid te oorweeg. (Vir elke toename van 1000m sal die spanning en stroom met 10% verminder word). | ||

| Lewensverwagting | 100000h(Un; Θhotspot ≤70 °C) | |

| Verwysingsstandaard | IEC 61071 ;IEC 61881; | |

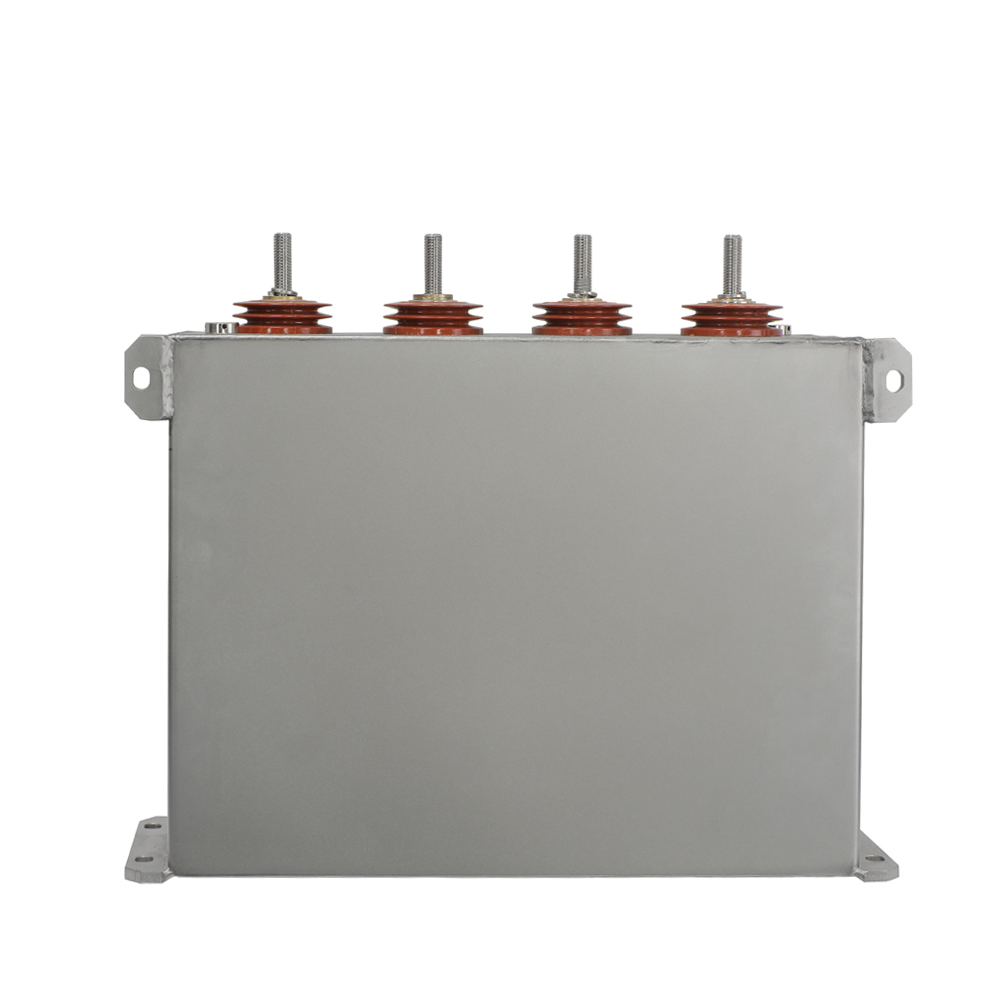

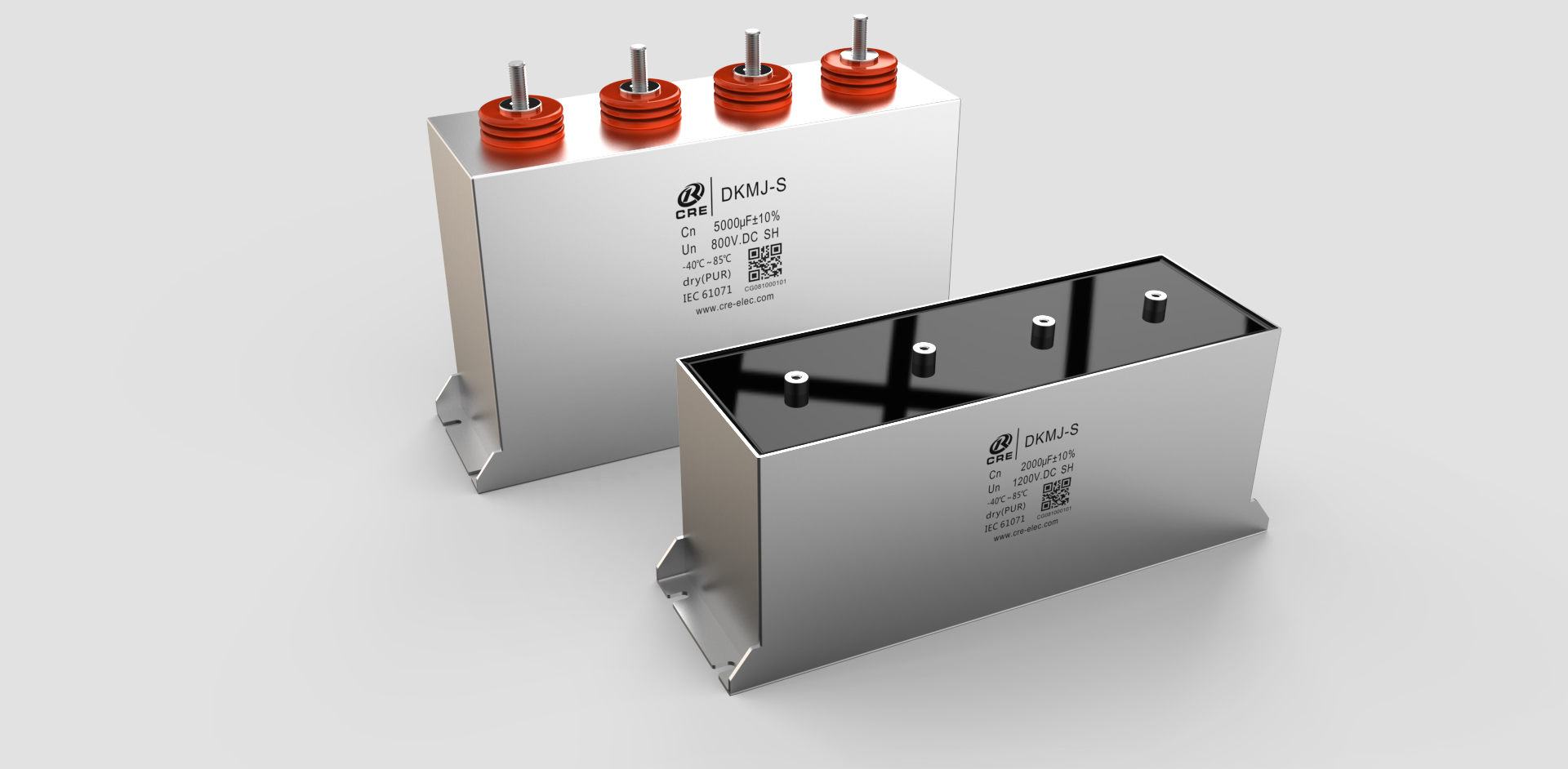

Kenmerk

1. Metaaldop-inkapseling, droë harsinfusie;

2. Kopermoer/skroefdrade, maklike installasie;

3. Groot kapasiteit, pasgemaakte afmeting;

4. Weerstand teen hoë spanning, met selfgenesende vermoë;

5. Hoë rimpelstroom, hoë dv / dt-weerstandsvermoë.

Spesifikasietabel

| Spanning | Ongeveer 800V.GS VSA 1200V Ur 200V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A) 50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Gewig (kg) |

| 4000 | 340 | 125 | 190 | 5 | 20.0 | 120 | 1.1 | 0.9 | 17.6 |

| 8000 | 340 | 125 | 350 | 4 | 32.0 | 180 | 0.72 | 0.6 | 31.2 |

| 6000 | 420 | 125 | 245 | 5 | 30.0 | 150 | 0.95 | 0.7 | 26.4 |

| 10000 | 420 | 125 | 360 | 4 | 40.0 | 200 | 0.72 | 0.5 | 39.2 |

| 12000 | 420 | 235 | 245 | 4 | 48.0 | 250 | 0.9 | 0.3 | 49.6 |

| 20000 | 420 | 235 | 360 | 3 | 60.0 | 300 | 0.6 | 0.3 | 73.6 |

| Spanning | Ongeveer 1200V.GS VSA 1800V Ur 300V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A) 50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Gewig (kg) |

| 2500 | 340 | 125 | 190 | 8 | 20.0 | 120 | 1.1 | 0.9 | 17.6 |

| 3300 | 340 | 125 | 245 | 8 | 26.4 | 150 | 0.95 | 0.7 | 22.4 |

| 5000 | 420 | 125 | 300 | 7 | 35.0 | 180 | 0.8 | 0.6 | 32.8 |

| 7500 | 420 | 125 | 430 | 5.5 | 41.3 | 200 | 0.66 | 0.6 | 44.8 |

| 5000 | 340 | 235 | 190 | 8 | 40.0 | 200 | 1.1 | 0.3 | 32.8 |

| 10000 | 340 | 235 | 350 | 6 | 60.0 | 250 | 0.8 | 0.3 | 58.4 |

| 5000 | 420 | 235 | 175 | 8 | 40.0 | 200 | 1 | 0.4 | 36 |

| 7500 | 420 | 235 | 245 | 7 | 52.5 | 250 | 0.9 | 0.3 | 49.6 |

| 10000 | 420 | 235 | 300 | 7 | 70.0 | 250 | 0.8 | 0.3 | 61.6 |

| 15000 | 420 | 235 | 430 | 5 | 75.0 | 300 | 0.6 | 0.3 | 84 |

| Spanning | Ongeveer 1500V.GS VSA 2250V Ur 450V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A) 50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Gewig (kg) |

| 1200 | 340 | 125 | 190 | 10 | 12.0 | 120 | 1.1 | 0.9 | 17.6 |

| 3000 | 340 | 125 | 420 | 8 | 24.0 | 180 | 0.66 | 0.7 | 37.6 |

| 2000 | 420 | 125 | 245 | 10 | 20.0 | 150 | 0.95 | 0.7 | 26.4 |

| 4000 | 420 | 125 | 430 | 8 | 32.0 | 200 | 0.66 | 0.6 | 44.8 |

| 5000 | 340 | 235 | 350 | 8 | 40.0 | 250 | 0.8 | 0.3 | 58.4 |

| 4000 | 420 | 235 | 245 | 10 | 40.0 | 250 | 0.9 | 0.3 | 49.6 |

| 8000 | 420 | 235 | 430 | 8 | 64.0 | 300 | 0.6 | 0.3 | 84 |

| Spanning | Ongeveer 2000V.GS VSA 3000V Ur 600V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A) 50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Gewig (kg) |

| 1000 | 340 | 125 | 245 | 12 | 12.0 | 150 | 0.95 | 0.7 | 22.4 |

| 1500 | 340 | 125 | 350 | 10 | 15.0 | 180 | 0.72 | 0.6 | 31.2 |

| 2000 | 420 | 125 | 360 | 10 | 20.0 | 200 | 0.72 | 0.5 | 39.2 |

| 2400 | 420 | 125 | 430 | 9 | 21.6 | 200 | 0.66 | 0.6 | 44.8 |

| 3200 | 340 | 235 | 350 | 10 | 32.0 | 250 | 0.8 | 0.3 | 46.4 |

| 4000 | 420 | 235 | 360 | 10 | 40.0 | 280 | 0.7 | 0.3 | 58.4 |

| 4800 | 420 | 235 | 430 | 9 | 43.2 | 300 | 0.6 | 0.3 | 67.2 |

| Spanning | Ongeveer 2200V.GS VSA 3300V Ur 600V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms (A)maks | ESR (mΩ) | Rth (K/W) | Gewig (kg) |

| 2000 | 420 | 235 | 245 | 12 | 24 | 150 | 0.9 | 0.740740741 | 40 |

| 2750 | 420 | 235 | 300 | 10 | 27.5 | 200 | 0.8 | 0.46875 | 49.6 |

| 3500 | 420 | 235 | 360 | 10 | 35 | 200 | 0.7 | 0.535714286 | 58.4 |

| Spanning | Ongeveer 3000V.GS VSA 4500V Ur 800V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms (A)maks | ESR (mΩ) | Rth (K/W) | Gewig (kg) |

| 1050 | 420 | 235 | 245 | 20 | 21 | 150 | 0.9 | 0.740740741 | 40 |

| 1400 | 420 | 235 | 300 | 15 | 21 | 200 | 0.8 | 0.46875 | 49.6 |

| 1800 | 420 | 235 | 360 | 15 | 27 | 200 | 0.7 | 0.535714286 | 58.4 |

| Spanning | Un 4000V.GS VSA 6000V Ur 1000V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms (A)maks | ESR (mΩ) | Rth (K/W) | Gewig (kg) |

| 600 | 420 | 235 | 245 | 20 | 12 | 150 | 0.9 | 0.740740741 | 40 |

| 800 | 420 | 235 | 300 | 20 | 16 | 200 | 0.8 | 0.46875 | 49.6 |

| 1000 | 420 | 235 | 360 | 20 | 20 | 200 | 0.7 | 0.535714286 | 58.4 |

| Spanning | Ongeveer 2800V.GS VSA 4200V Ur 800V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A) 50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Gewig (kg) |

| 2×1000 | 560 | 190 | 310 | 20 | 2×20 | 2×350 | 1 | 0.2 | 60 |

| Spanning | Un 3200V.GS VSA 4800V Ur 900V | ||||||||

| Cn (μF) | B (mm) | D (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A) 50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Gewig (kg) |

| 2×1200 | 340 | 175 | 950 | 15 | 2×18 | 2×200 | 1.0 | 0.5 | 95 |