OEM/ODM Verskaffer Aangepaste Kapasitor Vir Sonkragomsetter - Hoëkrag nuwe ontwerp filmkondensators – CRE

OEM/ODM Verskaffer Aangepaste Kapasitor Vir Sonkragomsetter - Hoëkrag nuwe ontwerp filmkondensators – CRE Besonderhede:

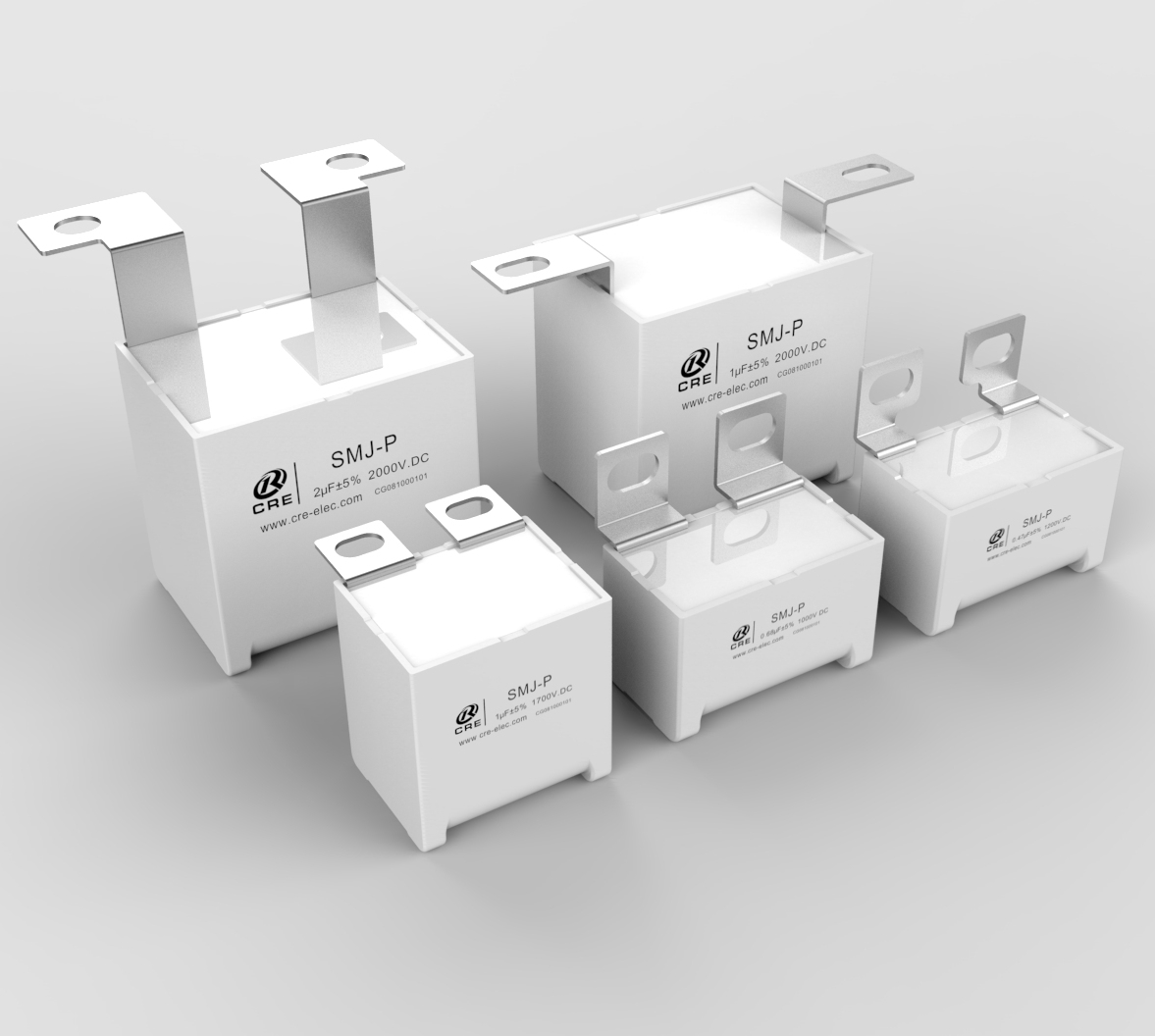

GS-skakelkondensator

GS-skakelkondensators vorm 'n noodsaaklike stadium in kragomskakeling vir baie toepassings.

Veeleisende toepassings het koste-, strawwe omgewings- en streng betroubaarheidsbeperkings. Alhoewel stroombaanontwerpe verskillende benaderings kan gebruik, sluit die langdurige kern van kragomskakelingsontwerpe GS-skakel-kondensators in.

GS-skakelkondensators kan die stelsel se energiedigtheid verbeter en die fisiese uitdagings van rimpelings oplos wat veroorsaak word deur vinnige skakeling wat inherent is aan skakelkragomskakelings.

Toepassing

Kragselektroniese kapasitors is komponente vir toerusting wat teen hoë krag werk. Kapasitors word gebruik om hierdie krag om te skakel en te beheer.

1. Driefase-pulswydtemodulasie (PWM) omsetters,

2. Fotovoltaïese en windkrag-omsetters

3. Industriële motoraandrywers

4. Motorlaaiers en omsetters in die motorbedryf

5. Mediese toerusting,

6. Kragtoevoer ens.

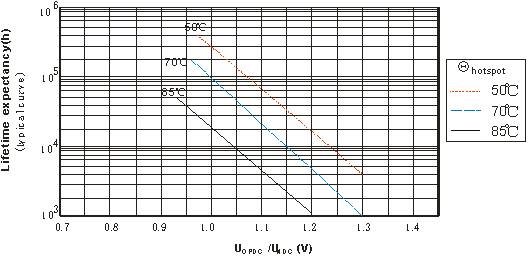

Lewensverwagting

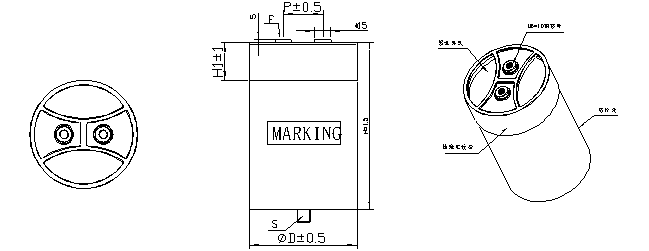

Oorsigtekening

| ΦD(mm) | P(mm) | H1(mm) | S | F | M |

| 76 | 32 | 20 | M12×16 | M6×10 | M8×20 |

| 86 | 32 | 20 | M12×16 | M6×10 | M8×20 |

| 96 | 45 | 20 | M12×16 | M6×10 | M8×20 |

| 116 | 50 | 22 | M12×16 | M6×10 | M8×20 |

| 136 | 50 | 30 | M16×25 | M6×10 | M8×20 |

| Spanning | 450V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 380 | 76 | 75 | 50 | 10 | 3.8 | 11.4 | 45 | 2.2 | 4.5 | 32 | 0.5 |

| 500 | 76 | 100 | 40 | 8 | 4.0 | 12.0 | 65 | 1.5 | 3.2 | 32 | 0.6 |

| 750 | 76 | 130 | 50 | 5 | 3.8 | 11.3 | 65 | 1.6 | 3.0 | 32 | 0.75 |

| 500 | 86 | 75 | 50 | 8 | 4.0 | 12.0 | 55 | 1.8 | 3.7 | 32 | 0.8 |

| 1000 | 86 | 130 | 50 | 5 | 5.0 | 15.0 | 70 | 1.5 | 2.7 | 32 | 1.1 |

| 650 | 86 | 100 | 40 | 5 | 3.3 | 9.8 | 75 | 1.2 | 3.0 | 32 | 0.9 |

| 650 | 86 | 95 | 40 | 5 | 3.3 | 9.8 | 75 | 1.2 | 3.0 | 32 | 0.85 |

| 650 | 96 | 75 | 50 | 5 | 3.3 | 9.8 | 60 | 1.5 | 3.7 | 45 | 0.75 |

| 1250 | 96 | 130 | 50 | 4 | 5.0 | 15.0 | 80 | 1 | 3.1 | 45 | 1.2 |

| 1800 | 116 | 130 | 50 | 4 | 7.2 | 21.6 | 85 | 0.8 | 3.5 | 50 | 1.6 |

| 1450 | 86 | 190 | 60 | 4 | 5.8 | 17.4 | 90 | 0.9 | 2.7 | 32 | 1.55 |

| 2700 | 116 | 190 | 60 | 3 | 8.1 | 24.3 | 100 | 0.8 | 2.5 | 50 | 2.45 |

| Spanning | 600V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 250 | 76 | 75 | 40 | 15 | 3.8 | 11.3 | 40 | 3.1 | 4.0 | 32 | 0.5 |

| 320 | 76 | 100 | 40 | 10 | 3.2 | 9.6 | 40 | 2.2 | 5.7 | 32 | 0.6 |

| 470 | 76 | 130 | 45 | 12 | 5.6 | 16.9 | 60 | 1.8 | 3.1 | 32 | 0.75 |

| 330 | 86 | 75 | 40 | 15 | 5.0 | 14.9 | 45 | 2.4 | 4.1 | 32 | 0.8 |

| 600 | 86 | 120 | 45 | 12 | 7.2 | 21.6 | 60 | 1.3 | 4.3 | 32 | 1.05 |

| 650 | 86 | 130 | 50 | 12 | 7.8 | 23.4 | 70 | 1.2 | 3.4 | 32 | 1.1 |

| 650 | 86 | 95 | 50 | 15 | 9.8 | 29.3 | 65 | 1.2 | 3.9 | 32 | 0.85 |

| 1000 | 86 | 180 | 50 | 12 | 12.0 | 36.0 | 70 | 1.5 | 2.7 | 32 | 1.5 |

| 420 | 96 | 75 | 45 | 15 | 6.3 | 18.9 | 50 | 2 | 4.0 | 45 | 0.75 |

| 800 | 96 | 130 | 60 | 12 | 9.6 | 28.8 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 950 | 116 | 100 | 60 | 10 | 9.5 | 28.5 | 90 | 1.2 | 2.1 | 50 | 1.25 |

| 1200 | 116 | 130 | 70 | 8 | 9.6 | 28.8 | 80 | 1.2 | 2.6 | 50 | 1.6 |

| 1800 | 116 | 180 | 50 | 8 | 14.4 | 43.2 | 80 | 1.2 | 2.6 | 50 | 2.4 |

| 2700 | 116 | 260 | 70 | 5 | 13.5 | 40.5 | 100 | 0.9 | 2.2 | 50 | 3.2 |

| 2500 | 136 | 180 | 60 | 5 | 12.5 | 37.5 | 100 | 0.8 | 2.5 | 50 | 3.7 |

| 3750 | 136 | 260 | 70 | 4 | 15.0 | 45.0 | 115 | 0.7 | 2.2 | 50 | 4.7 |

| Spanning | 700V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 200 | 76 | 75 | 40 | 15 | 3.0 | 9.0 | 40 | 4 | 3.1 | 32 | 0.5 |

| 400 | 76 | 130 | 45 | 15 | 6.0 | 18.0 | 60 | 2 | 2.8 | 32 | 0.75 |

| 420 | 76 | 130 | 50 | 15 | 6.3 | 18.9 | 60 | 2 | 2.8 | 32 | 0.75 |

| 600 | 86 | 125 | 60 | 15 | 9.0 | 27.0 | 45 | 3.2 | 3.1 | 32 | 1.05 |

| 550 | 86 | 130 | 50 | 12 | 6.6 | 19.8 | 65 | 1.8 | 2.6 | 32 | 1.1 |

| 680 | 96 | 130 | 45 | 12 | 8.2 | 24.5 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 720 | 96 | 125 | 60 | 12 | 8.6 | 25.9 | 55 | 2.6 | 2.5 | 45 | 1.15 |

| 1000 | 116 | 130 | 50 | 10 | 10.0 | 30.0 | 80 | 1 | 3.1 | 50 | 1.6 |

| 1000 | 96 | 180 | 60 | 10 | 10.0 | 30.0 | 75 | 1.2 | 3.0 | 45 | 1.6 |

| 1500 | 116 | 180 | 60 | 7 | 10.5 | 31.5 | 85 | 0.9 | 3.1 | 50 | 2.4 |

| 2000 | 116 | 230 | 70 | 7 | 14.0 | 42.0 | 85 | 0.8 | 3.5 | 50 | 3 |

| 2000 | 136 | 180 | 60 | 7 | 14.0 | 42.0 | 90 | 0.75 | 3.3 | 50 | 3.7 |

| 3000 | 136 | 230 | 70 | 5 | 15.0 | 45.0 | 100 | 0.7 | 2.9 | 50 | 4.2 |

| 3300 | 136 | 260 | 70 | 5 | 16.5 | 49.5 | 120 | 0.6 | 2.3 | 50 | 4.7 |

| Spanning | 800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 110 | 86 | 80 | 45 | 20 | 2.2 | 6.6 | 75 | 2 | 1.8 | 32 | 0.8 |

| 150 | 86 | 95 | 45 | 20 | 3.0 | 9.0 | 80 | 1.5 | 2.1 | 32 | 0.85 |

| 250 | 86 | 75 | 45 | 15 | 3.8 | 11.3 | 45 | 3.1 | 3.2 | 32 | 0.8 |

| 360 | 86 | 130 | 55 | 12 | 4.3 | 13.0 | 65 | 2.2 | 2.2 | 32 | 1.1 |

| 470 | 86 | 130 | 45 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.1 |

| 600 | 96 | 130 | 55 | 10 | 6.0 | 18.0 | 75 | 2.2 | 1.6 | 45 | 1.2 |

| 730 | 86 | 180 | 55 | 10 | 7.3 | 21.9 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 750 | 86 | 180 | 55 | 12 | 9.0 | 27.0 | 75 | 1.8 | 2.0 | 32 | 1.5 |

| 1000 | 96 | 180 | 60 | 10 | 10.0 | 30.0 | 75 | 1.3 | 2.7 | 45 | 1.6 |

| 900 | 116 | 130 | 65 | 7 | 6.3 | 18.9 | 80 | 1.4 | 2.2 | 50 | 1.6 |

| 1400 | 116 | 180 | 65 | 7 | 9.8 | 29.4 | 80 | 0.9 | 3.5 | 50 | 2.4 |

| 1000 | 116 | 125 | 60 | 7 | 7.0 | 21.0 | 70 | 1.4 | 2.9 | 50 | 1.55 |

| 2000 | 116 | 230 | 65 | 5 | 10.0 | 30.0 | 85 | 0.9 | 3.1 | 50 | 3 |

| 2800 | 136 | 230 | 70 | 5 | 14.0 | 42.0 | 100 | 0.8 | 2.5 | 50 | 4.2 |

| Spanning | 900V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 160 | 76 | 75 | 40 | 15 | 3.0 | 9.0 | 35 | 3 | 5.4 | 32 | 0.5 |

| 320 | 76 | 130 | 50 | 15 | 5.0 | 14.9 | 60 | 3.2 | 1.7 | 32 | 0.75 |

| 350 | 76 | 125 | 50 | 15 | 5.0 | 15.0 | 40 | 2.8 | 4.5 | 32 | 0.75 |

| 210 | 86 | 75 | 40 | 15 | 3.2 | 9.5 | 40 | 2.2 | 5.7 | 32 | 0.8 |

| 450 | 86 | 125 | 45 | 12 | 5.4 | 16.2 | 50 | 2.7 | 3.0 | 32 | 1.1 |

| 420 | 86 | 130 | 45 | 12 | 5.0 | 15.1 | 65 | 2.5 | 1.9 | 32 | 1.1 |

| 490 | 86 | 120 | 45 | 10 | 4.9 | 14.7 | 70 | 1.8 | 2.3 | 32 | 1.05 |

| 510 | 86 | 120 | 45 | 10 | 5.1 | 15.3 | 70 | 1.8 | 2.3 | 32 | 1.05 |

| 660 | 86 | 180 | 50 | 10 | 6.6 | 19.8 | 70 | 2 | 2.0 | 32 | 1.5 |

| 900 | 86 | 230 | 50 | 10 | 9.0 | 27.0 | 65 | 2.1 | 2.3 | 32 | 1.8 |

| 580 | 96 | 125 | 50 | 10 | 5.8 | 17.4 | 55 | 3.3 | 2.0 | 45 | 1.2 |

| 540 | 96 | 130 | 50 | 7 | 3.8 | 11.3 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 630 | 116 | 100 | 55 | 7 | 4.4 | 13.2 | 60 | 2 | 2.8 | 50 | 1.3 |

| 860 | 116 | 125 | 55 | 7 | 6.0 | 18.1 | 60 | 2.2 | 2.5 | 50 | 1.55 |

| 810 | 116 | 130 | 60 | 7 | 5.7 | 17.0 | 80 | 1.2 | 2.6 | 50 | 1.6 |

| 1250 | 116 | 180 | 60 | 7 | 8.8 | 26.3 | 80 | 1.2 | 2.6 | 50 | 2.4 |

| 1700 | 116 | 230 | 60 | 5 | 8.5 | 25.5 | 80 | 1.1 | 2.8 | 50 | 3 |

| 1700 | 136 | 180 | 65 | 6 | 10.2 | 30.6 | 100 | 0.9 | 2.2 | 50 | 3.7 |

| 2400 | 136 | 230 | 70 | 5 | 12.0 | 36.0 | 100 | 0.95 | 2.1 | 50 | 4.2 |

| Spanning | 1100V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 130 | 76 | 75 | 40 | 15 | 1.9 | 5.6 | 35 | 4.5 | 3.6 | 32 | 0.5 |

| 260 | 76 | 130 | 45 | 15 | 3.8 | 11.3 | 60 | 2.8 | 2.0 | 32 | 0.75 |

| 280 | 76 | 125 | 50 | 12 | 3.3 | 9.9 | 35 | 4 | 4.1 | 32 | 0.75 |

| 170 | 86 | 75 | 50 | 15 | 2.6 | 7.7 | 45 | 5 | 2.0 | 32 | 0.8 |

| 360 | 86 | 125 | 55 | 12 | 4.3 | 13.0 | 35 | 2.5 | 6.5 | 32 | 1.1 |

| 330 | 86 | 130 | 45 | 15 | 5.0 | 15.0 | 65 | 2.8 | 1.7 | 32 | 1.1 |

| 420 | 86 | 136 | 45 | 12 | 5.0 | 15.0 | 60 | 2 | 2.8 | 32 | 1.15 |

| 420 | 86 | 155 | 45 | 12 | 5.0 | 15.0 | 65 | 1.5 | 3.2 | 32 | 1.25 |

| 470 | 86 | 180 | 60 | 10 | 4.7 | 14.1 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 500 | 86 | 180 | 60 | 10 | 5.0 | 15.0 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 600 | 86 | 225 | 60 | 10 | 6.0 | 18.0 | 80 | 1.2 | 2.6 | 32 | 1.8 |

| 600 | 86 | 225 | 70 | 10 | 6.0 | 18.0 | 60 | 2.2 | 2.5 | 32 | 1.8 |

| 600 | 116 | 130 | 50 | 10 | 6.0 | 18.0 | 75 | 1.8 | 2.0 | 50 | 1.6 |

| 680 | 86 | 225 | 70 | 12 | 8.2 | 24.5 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 720 | 86 | 230 | 70 | 12 | 8.6 | 25.9 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 460 | 96 | 125 | 65 | 10 | 4.6 | 13.8 | 55 | 3.2 | 2.1 | 45 | 1.2 |

| 520 | 96 | 180 | 65 | 12 | 6.2 | 18.7 | 75 | 1.5 | 2.4 | 45 | 1.6 |

| 500 | 116 | 100 | 70 | 10 | 5.0 | 15.0 | 55 | 2.5 | 2.6 | 50 | 1.3 |

| 680 | 116 | 125 | 70 | 10 | 6.8 | 20.4 | 60 | 2.8 | 2.0 | 50 | 1.6 |

| 650 | 116 | 130 | 75 | 10 | 6.5 | 19.5 | 75 | 1.3 | 2.7 | 50 | 1.6 |

| 1000 | 116 | 180 | 75 | 12 | 12.0 | 36.0 | 75 | 1.5 | 2.4 | 50 | 2.4 |

| 1200 | 116 | 230 | 80 | 8 | 9.6 | 28.8 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1200 | 116 | 230 | 75 | 12 | 14.4 | 43.2 | 105 | 0.9 | 2.0 | 50 | 3 |

| 1250 | 116 | 230 | 75 | 12 | 15.0 | 45.0 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1300 | 116 | 230 | 75 | 12 | 15.6 | 46.8 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1400 | 136 | 180 | 70 | 7 | 9.8 | 29.4 | 85 | 1.3 | 2.1 | 50 | 3.7 |

| 1700 | 136 | 230 | 70 | 5 | 8.5 | 25.5 | 100 | 1.4 | 1.4 | 50 | 4.2 |

| 1900 | 136 | 230 | 75 | 5 | 9.5 | 28.5 | 100 | 1.2 | 1.7 | 50 | 4.2 |

| 2800 | 136 | 335 | 80 | 5 | 14.0 | 42.0 | 120 | 0.8 | 1.7 | 50 | 6.1 |

| 3060 | 136 | 345 | 80 | 5 | 15.3 | 45.9 | 120 | 0.9 | 1.5 | 50 | 6.2 |

| 3200 | 136 | 335 | 80 | 5 | 16.0 | 48.0 | 120 | 0.85 | 1.6 | 50 | 6.1 |

| Spanning | 1200V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 170 | 86 | 75 | 50 | 15 | 2.6 | 7.7 | 45 | 4.5 | 2.2 | 32 | 0.8 |

| 420 | 76 | 145 | 50 | 15 | 6.3 | 18.9 | 30 | 12 | 1.9 | 32 | 0.85 |

| 330 | 86 | 130 | 45 | 15 | 5.0 | 15.0 | 65 | 2.8 | 1.7 | 32 | 1.1 |

| 420 | 86 | 136 | 45 | 12 | 5.0 | 15.0 | 65 | 2 | 2.4 | 32 | 1.15 |

| 420 | 86 | 155 | 45 | 12 | 5.0 | 15.0 | 70 | 1.5 | 2.7 | 32 | 1.25 |

| 420 | 116 | 95 | 55 | 10 | 4.2 | 12.6 | 80 | 1.4 | 2.2 | 50 | 1.2 |

| 450 | 86 | 160 | 55 | 12 | 5.4 | 16.2 | 70 | 2.9 | 1.4 | 32 | 1.3 |

| 470 | 86 | 180 | 60 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.5 |

| 470 | 86 | 225 | 60 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.8 |

| 550 | 86 | 145 | 55 | 12 | 6.6 | 19.8 | 40 | 11 | 1.1 | 32 | 1,2 |

| 600 | 86 | 225 | 60 | 10 | 6.0 | 18.0 | 80 | 1.2 | 2.6 | 32 | 1.8 |

| 600 | 86 | 225 | 70 | 10 | 6.0 | 18.0 | 60 | 2.2 | 2.5 | 32 | 1.8 |

| 600 | 116 | 130 | 50 | 10 | 6.0 | 18.0 | 75 | 1.8 | 2.0 | 50 | 1.6 |

| 680 | 86 | 225 | 70 | 12 | 8.2 | 24.5 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 500 | 116 | 100 | 65 | 10 | 5.0 | 15.0 | 55 | 2.6 | 2.5 | 50 | 1.2 |

| 680 | 116 | 125 | 65 | 10 | 6.8 | 20.4 | 50 | 2.8 | 2.9 | 50 | 1.55 |

| 650 | 116 | 130 | 65 | 10 | 6.5 | 19.5 | 80 | 1.8 | 1.7 | 50 | 1.6 |

| 1000 | 116 | 180 | 70 | 7 | 7.0 | 21.0 | 75 | 1.3 | 2.7 | 50 | 2.4 |

| 1200 | 116 | 230 | 70 | 7 | 8.4 | 25.2 | 75 | 1.3 | 2.7 | 50 | 3 |

| 1250 | 116 | 230 | 70 | 7 | 8.8 | 26.3 | 75 | 1.2 | 3.0 | 50 | 3 |

| 1400 | 136 | 180 | 75 | 7 | 9.8 | 29.4 | 85 | 1.1 | 2.5 | 50 | 3.7 |

| 1700 | 136 | 230 | 80 | 5 | 8.5 | 25.5 | 85 | 1 | 2.8 | 50 | 4.2 |

| 850 | 136 | 125 | 70 | 8 | 6.8 | 20.4 | 75 | 1.6 | 2.2 | 50 | 1.9 |

| 950 | 136 | 125 | 60 | 8 | 7.6 | 22.8 | 80 | 1.1 | 2.8 | 50 | 2.4 |

| 1200 | 116 | 180 | 80 | 8 | 9.6 | 28.8 | 80 | 1 | 3.1 | 50 | 2.4 |

| 1200 | 116 | 180 | 60 | 5 | 6.0 | 18.0 | 100 | 0.8 | 2.5 | 50 | 2.4 |

| 1500 | 136 | 180 | 70 | 5 | 7.5 | 22.5 | 100 | 0.9 | 2.2 | 50 | 3.7 |

| 2700 | 136 | 335 | 80 | 5 | 13.5 | 40.5 | 110 | 0.85 | 1.9 | 50 | 6.1 |

| Spanning | 1300V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 230 | 86 | 125 | 50 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 210 | 86 | 130 | 50 | 15 | 3.2 | 9.5 | 70 | 2 | 2.0 | 32 | 1.1 |

| 330 | 86 | 180 | 60 | 15 | 5.0 | 14.9 | 65 | 3 | 1.6 | 32 | 1.5 |

| 470 | 86 | 230 | 65 | 12 | 5.6 | 16.9 | 65 | 3.2 | 1.5 | 32 | 1.8 |

| 410 | 116 | 130 | 65 | 12 | 4.9 | 14.8 | 80 | 1.8 | 1.7 | 50 | 1.6 |

| 650 | 116 | 180 | 65 | 10 | 6.5 | 19.5 | 85 | 2 | 1.4 | 50 | 2.4 |

| 880 | 116 | 230 | 80 | 10 | 8.8 | 26.4 | 85 | 2.2 | 1.3 | 50 | 3 |

| 900 | 136 | 180 | 70 | 7 | 6.3 | 18.9 | 100 | 1.6 | 1.3 | 50 | 3.7 |

| 1200 | 136 | 230 | 80 | 7 | 8.4 | 25.2 | 105 | 1.5 | 1.2 | 50 | 4.2 |

| Spanning | 1500V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 160 | 86 | 125 | 50 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 160 | 86 | 130 | 50 | 15 | 2.4 | 7.2 | 60 | 3.5 | 1.6 | 32 | 1.1 |

| 240 | 86 | 180 | 55 | 15 | 3.6 | 10.8 | 65 | 5 | 0.9 | 32 | 1.5 |

| 320 | 86 | 230 | 55 | 12 | 3.8 | 11.5 | 60 | 3.5 | 1.6 | 32 | 1.8 |

| 300 | 116 | 130 | 55 | 12 | 3.6 | 10.8 | 75 | 2 | 1.8 | 50 | 1.6 |

| 470 | 116 | 180 | 60 | 10 | 4.7 | 14.1 | 75 | 2.8 | 1.3 | 50 | 2.4 |

| 650 | 116 | 230 | 60 | 10 | 6.5 | 19.5 | 80 | 2.8 | 1.1 | 50 | 3 |

| 660 | 136 | 180 | 60 | 7 | 4.6 | 13.9 | 100 | 1.8 | 1.1 | 50 | 3.7 |

| 900 | 136 | 230 | 60 | 6 | 5.4 | 16.2 | 105 | 1.2 | 1.5 | 50 | 4.2 |

| 1000 | 136 | 260 | 70 | 5 | 5.0 | 15.0 | 120 | 0.9 | 1.5 | 50 | 4.7 |

| Spanning | 1800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 130 | 86 | 125 | 55 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 120 | 86 | 130 | 55 | 15 | 1.8 | 5.4 | 60 | 2.5 | 2.2 | 32 | 1.1 |

| 180 | 86 | 180 | 60 | 15 | 2.7 | 8.1 | 65 | 2 | 2.4 | 32 | 1.5 |

| 260 | 86 | 230 | 60 | 12 | 3.1 | 9.4 | 60 | 3 | 1.9 | 32 | 1.8 |

| 230 | 116 | 130 | 60 | 12 | 2.8 | 8.3 | 80 | 2 | 1.6 | 50 | 1.6 |

| 360 | 116 | 180 | 65 | 10 | 3.6 | 10.8 | 80 | 3.2 | 1.0 | 50 | 2.4 |

| 500 | 116 | 230 | 70 | 10 | 5.0 | 15.0 | 75 | 3 | 1.2 | 50 | 3 |

| 510 | 136 | 180 | 70 | 7 | 3.6 | 10.7 | 100 | 2 | 1.0 | 50 | 3.7 |

| 680 | 136 | 230 | 70 | 7 | 4.8 | 14.3 | 95 | 2 | 1.1 | 50 | 4.2 |

| Spanning | 2000V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 100 | 86 | 125 | 55 | 15 | 1.5 | 4.5 | 35 | 3.8 | 4.3 | 32 | 1.1 |

| 90 | 86 | 130 | 55 | 15 | 1.4 | 4.1 | 65 | 2.5 | 1.9 | 32 | 1.1 |

| 150 | 86 | 180 | 60 | 15 | 2.3 | 6.8 | 60 | 3.5 | 1.6 | 32 | 1.5 |

| 200 | 86 | 230 | 60 | 12 | 2.4 | 7.2 | 65 | 2 | 2.4 | 32 | 1.8 |

| 180 | 116 | 130 | 65 | 10 | 1.8 | 5.4 | 75 | 2.5 | 1.4 | 50 | 1.6 |

| 280 | 116 | 180 | 70 | 10 | 2.8 | 8.4 | 70 | 2 | 2.0 | 50 | 2.4 |

| 380 | 116 | 230 | 80 | 10 | 3.8 | 11.4 | 80 | 2 | 1.6 | 50 | 3 |

| 400 | 136 | 180 | 60 | 7 | 2.8 | 8.4 | 100 | 1.6 | 1.3 | 50 | 3.7 |

| 550 | 136 | 230 | 70 | 7 | 3.9 | 11.6 | 100 | 1.5 | 1.3 | 50 | 4.2 |

| 850 | 136 | 335 | 80 | 5 | 4.3 | 12.8 | 120 | 1.1 | 1.3 | 50 | 6.1 |

| Spanning | 2800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 160 | 116 | 180 | 70 | 30 | 4.8 | 14.4 | 75 | 2.2 | 1.6 | 50 | 2.4 |

| 210 | 116 | 230 | 75 | 25 | 5.3 | 15.8 | 70 | 2.8 | 1.5 | 50 | 3 |

| 225 | 136 | 180 | 75 | 20 | 4.5 | 13.5 | 85 | 2 | 1.4 | 50 | 3.7 |

| 300 | 136 | 230 | 80 | 15 | 4.5 | 13.5 | 80 | 2.5 | 1.3 | 50 | 4.2 |

| Spanning | 4000V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 70 | 116 | 180 | 70 | 50 | 3.5 | 10.5 | 70 | 3.5 | 1.2 | 50 | 2.4 |

| 95 | 116 | 230 | 75 | 40 | 3.8 | 11.4 | 70 | 3.6 | 1.1 | 50 | 3 |

| 100 | 136 | 180 | 75 | 35 | 3.5 | 10.5 | 85 | 3 | 0.9 | 50 | 3.7 |

| 135 | 136 | 230 | 80 | 30 | 4.1 | 12.2 | 80 | 3.5 | 0.9 | 50 | 4.2 |

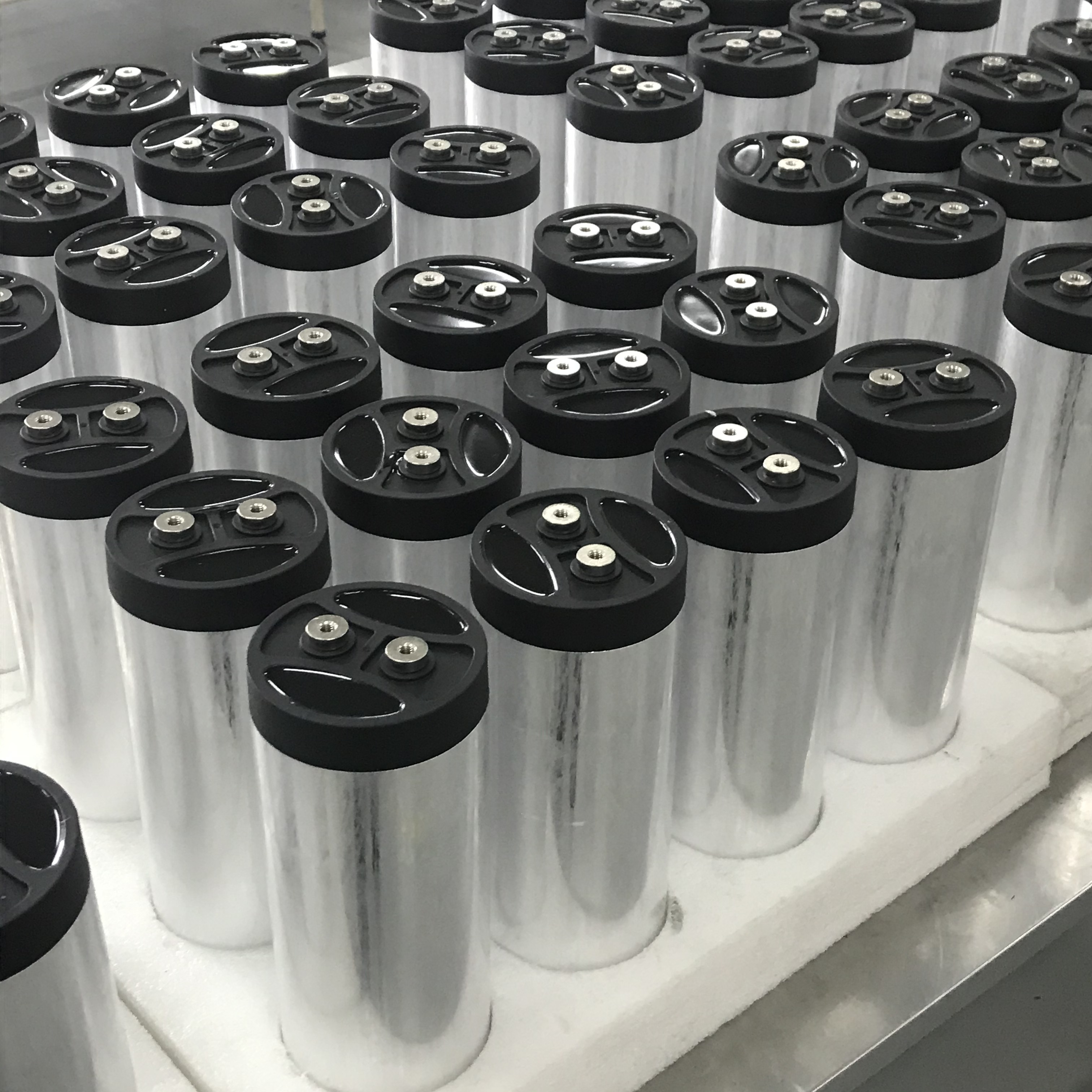

Produk detail foto's:

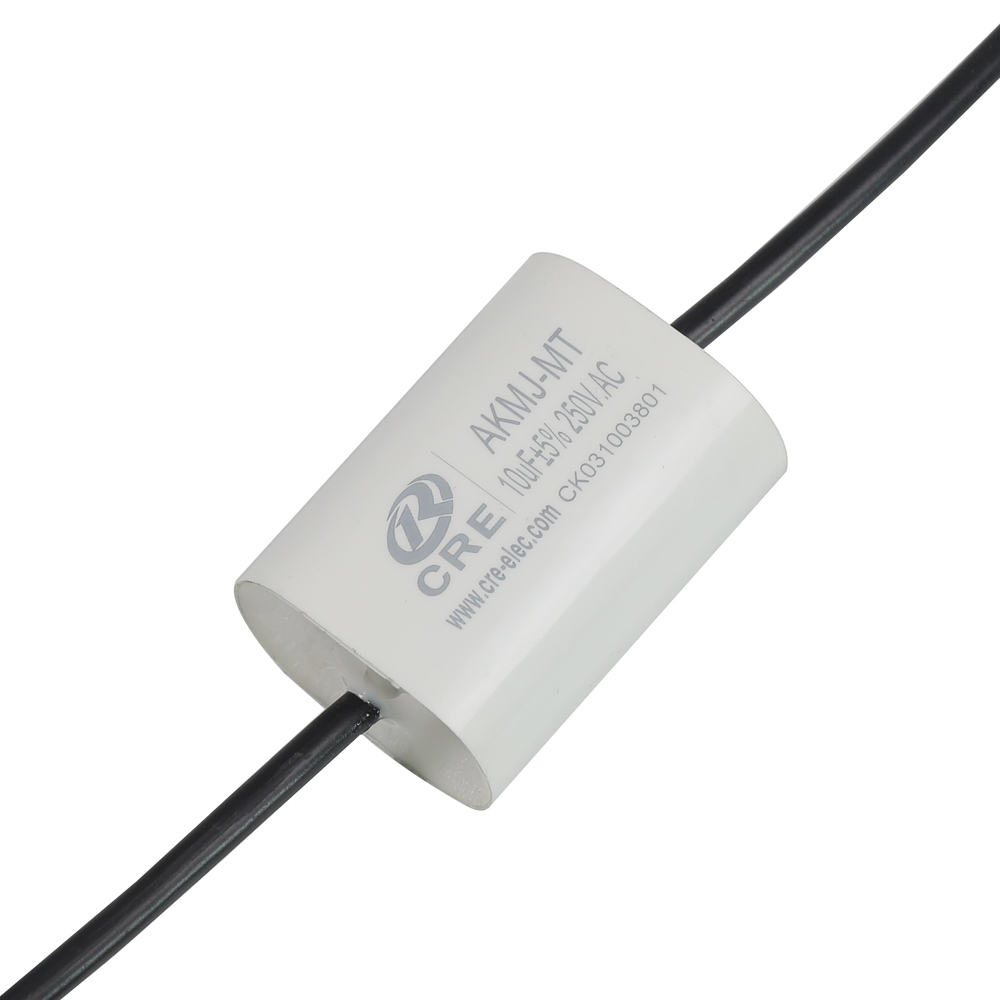

Verwante produkgids:

Ons is daartoe verbind om u die aggressiewe prys, uitsonderlike produkte en oplossings van hoë gehalte, sowel as vinnige aflewering vir OEM/ODM Verskaffer Pasgemaakte Kondensator Vir Sonkragomsetter - Hoëkrag nuwe ontwerp filmkondensators - CRE, te bied. Die produk sal aan die hele wêreld verskaf word, soos: Dubai, Kaïro, Philadelphia. Ons maandelikse produksie is meer as 5000 stuks. Ons het 'n streng gehaltebeheerstelsel opgestel. Kontak ons gerus vir verdere inligting. Ons hoop dat ons langtermyn sakeverhoudings met u kan vestig en sake op 'n wedersyds voordelige basis kan doen. Ons doen en sal altyd ons bes doen om u te dien.

Die verskaffer hou by die teorie van "kwaliteit die basiese, vertroue die eerste en bestuur die gevorderde" sodat hulle 'n betroubare produkgehalte en stabiele kliënte kan verseker.