Gewilde ontwerp vir gemetalliseerde filmkondensatoroplossing - Hoëspanning selfhelende filmkondensator in elektroniese en elektriese toestelle – CRE

Gewilde Ontwerp vir Gemetalliseerde Filmkondensatoroplossing - Hoëspanning selfhelende filmkondensator in elektroniese en elektriese toestelle – CRE Besonderhede:

Tegniese data

| Bedryfstemperatuurreeks | Maks. Bedryfstemperatuur., Top, maks: +85 ℃ Boonste kategorie temperatuur: +70 ℃ Laer kategorie temperatuur: -40 ℃ | |

| kapasitansiebereik | 50μF~4000μF | |

| On/ Nominale spanning On | 450V.GS~4000V.GS | |

| Kap.tol | ±5%(J); ±10%(K) | |

| Weerstaan spanning | Vt-t | 1.5Un GS/60S |

| Vt-c | 1000+2×Un/√2 (V.AC) 60S (min3000 V.AC) | |

| Oorspanning | 1.1Un(30% van die duur van die lading) | |

| 1.15Un(30min/dag) | ||

| 1.2Un(5min/dag) | ||

| 1.3Un(1min/dag) | ||

| 1.5Un (100ms elke keer, 1000 keer gedurende die leeftyd) | ||

| Dissipasiefaktor | tgδ≤0.003 f=100Hz | |

| tgδ0≤0.0002 | ||

| Isolasieweerstand | Rs*C≥10000S (teen 20℃ 100V.DC 60s) | |

| Vlamvertraging | UL94V-0 | |

| Maksimum vermoë | 3500m | |

| Wanneer die hoogte bo 3500m tot binne 5500m is, is dit nodig om die gebruik van 'n verminderde hoeveelheid te oorweeg. (Vir elke toename van 1000m sal die spanning en stroom met 10% verminder word).

| ||

| Lewensverwagting | 100 000h(Un; Θhotspot≤70 °C) | |

| Verwysingsstandaard | IEC61071 ;GB/T17702; | |

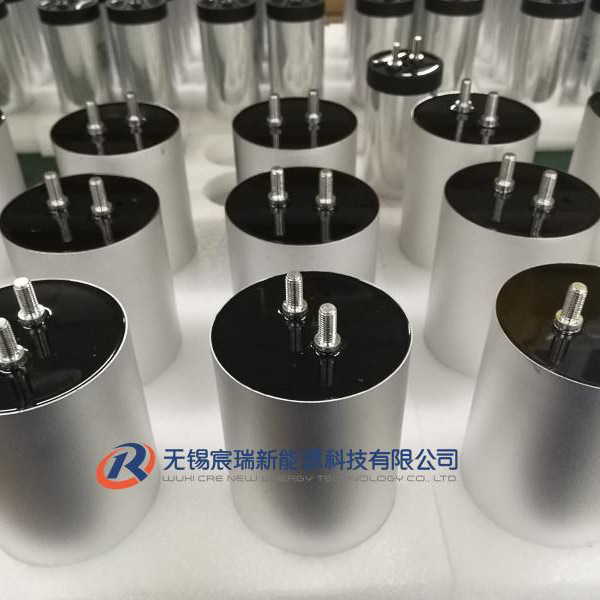

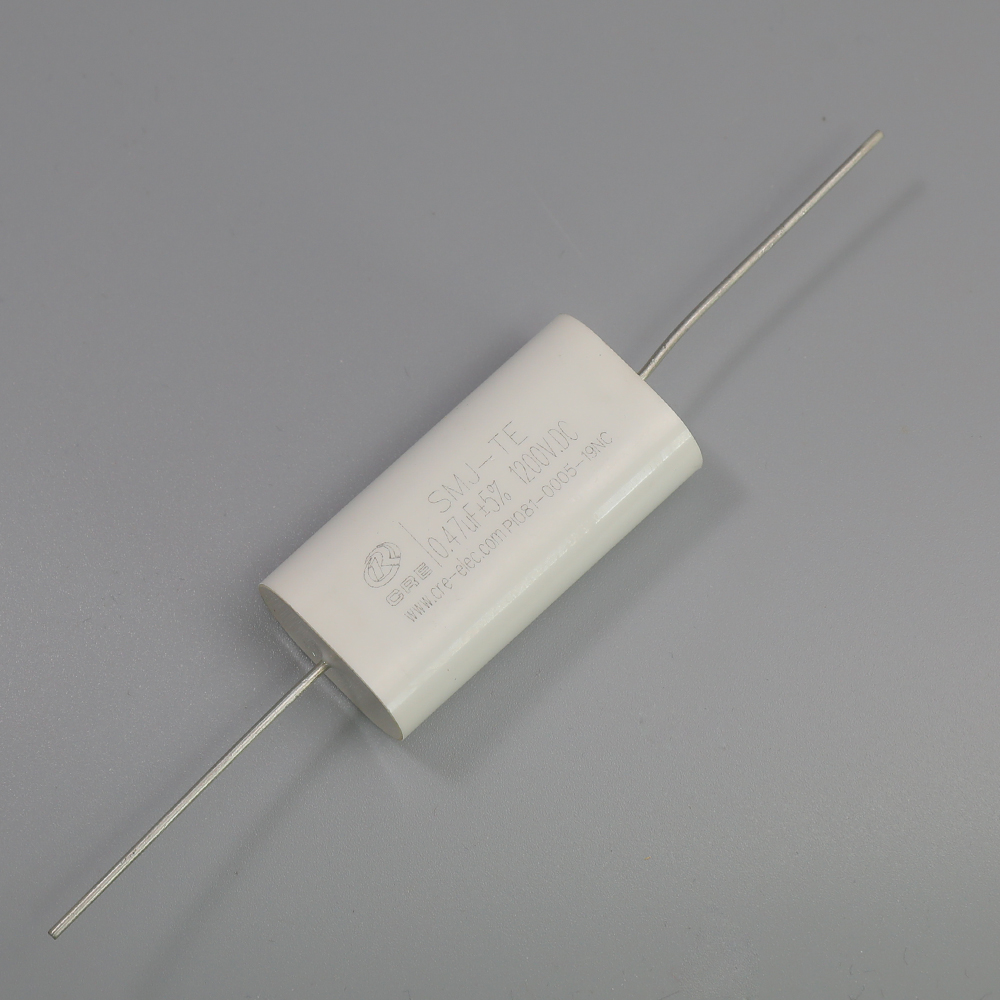

Kenmerk

1. Aluminium blikverpakking, droë harsinfusie;

2. Skroef-/moerdrade, maklike installasie;

3. Groot kapasiteit, klein grootte;

4. Weerstand teen hoë spanning, met selfgenesing;

5. Hoë rimpelstroom, hoë dv / dt-weerstandsvermoë.

Soos ander CRE-produkte, het die reekskondensator 'n UL-sertifikaat en is 100% inbrandtoets gedoen.

Toepassing

1. Kragomsetter;

2. Aangedrewe stelsel;

3. Hysstelsel;

4. Laaitoestel;

5. AFP-, SVG-, SVC-toestelle;

6. Kraggehalte.

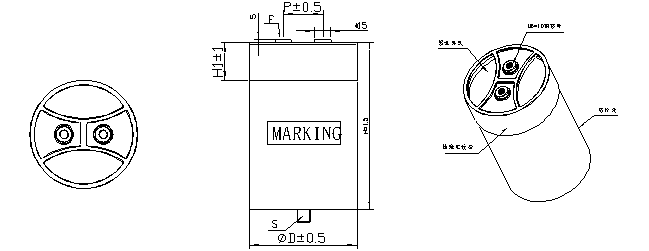

Oorsigtekening

| ΦD(mm) | P(mm) | H1(mm) | S | F | M |

| 76 | 32 | 20 | M12×16 | M6×10 | M8×20 |

| 86 | 32 | 20 | M12×16 | M6×10 | M8×20 |

| 96 | 45 | 20 | M12×16 | M6×10 | M8×20 |

| 116 | 50 | 22 | M12×16 | M6×10 | M8×20 |

| 136 | 50 | 30 | M16×25 | M6×10 | M8×20 |

| Spanning | 450V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 380 | 76 | 75 | 50 | 10 | 3.8 | 11.4 | 45 | 2.2 | 4.5 | 32 | 0.5 |

| 500 | 76 | 100 | 40 | 8 | 4.0 | 12.0 | 65 | 1.5 | 3.2 | 32 | 0.6 |

| 750 | 76 | 130 | 50 | 5 | 3.8 | 11.3 | 65 | 1.6 | 3.0 | 32 | 0.75 |

| 500 | 86 | 75 | 50 | 8 | 4.0 | 12.0 | 55 | 1.8 | 3.7 | 32 | 0.8 |

| 1000 | 86 | 130 | 50 | 5 | 5.0 | 15.0 | 70 | 1.5 | 2.7 | 32 | 1.1 |

| 650 | 86 | 100 | 40 | 5 | 3.3 | 9.8 | 75 | 1.2 | 3.0 | 32 | 0.9 |

| 650 | 86 | 95 | 40 | 5 | 3.3 | 9.8 | 75 | 1.2 | 3.0 | 32 | 0.85 |

| 650 | 96 | 75 | 50 | 5 | 3.3 | 9.8 | 60 | 1.5 | 3.7 | 45 | 0.75 |

| 1250 | 96 | 130 | 50 | 4 | 5.0 | 15.0 | 80 | 1 | 3.1 | 45 | 1.2 |

| 1800 | 116 | 130 | 50 | 4 | 7.2 | 21.6 | 85 | 0.8 | 3.5 | 50 | 1.6 |

| 1450 | 86 | 190 | 60 | 4 | 5.8 | 17.4 | 90 | 0.9 | 2.7 | 32 | 1.55 |

| 2700 | 116 | 190 | 60 | 3 | 8.1 | 24.3 | 100 | 0.8 | 2.5 | 50 | 2.45 |

| Spanning | 600V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 250 | 76 | 75 | 40 | 15 | 3.8 | 11.3 | 40 | 3.1 | 4.0 | 32 | 0.5 |

| 320 | 76 | 100 | 40 | 10 | 3.2 | 9.6 | 40 | 2.2 | 5.7 | 32 | 0.6 |

| 470 | 76 | 130 | 45 | 12 | 5.6 | 16.9 | 60 | 1.8 | 3.1 | 32 | 0.75 |

| 330 | 86 | 75 | 40 | 15 | 5.0 | 14.9 | 45 | 2.4 | 4.1 | 32 | 0.8 |

| 600 | 86 | 120 | 45 | 12 | 7.2 | 21.6 | 60 | 1.3 | 4.3 | 32 | 1.05 |

| 650 | 86 | 130 | 50 | 12 | 7.8 | 23.4 | 70 | 1.2 | 3.4 | 32 | 1.1 |

| 650 | 86 | 95 | 50 | 15 | 9.8 | 29.3 | 65 | 1.2 | 3.9 | 32 | 0.85 |

| 1000 | 86 | 180 | 50 | 12 | 12.0 | 36.0 | 70 | 1.5 | 2.7 | 32 | 1.5 |

| 420 | 96 | 75 | 45 | 15 | 6.3 | 18.9 | 50 | 2 | 4.0 | 45 | 0.75 |

| 800 | 96 | 130 | 60 | 12 | 9.6 | 28.8 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 950 | 116 | 100 | 60 | 10 | 9.5 | 28.5 | 90 | 1.2 | 2.1 | 50 | 1.25 |

| 1200 | 116 | 130 | 70 | 8 | 9.6 | 28.8 | 80 | 1.2 | 2.6 | 50 | 1.6 |

| 1800 | 116 | 180 | 50 | 8 | 14.4 | 43.2 | 80 | 1.2 | 2.6 | 50 | 2.4 |

| 2700 | 116 | 260 | 70 | 5 | 13.5 | 40.5 | 100 | 0.9 | 2.2 | 50 | 3.2 |

| 2500 | 136 | 180 | 60 | 5 | 12.5 | 37.5 | 100 | 0.8 | 2.5 | 50 | 3.7 |

| 3750 | 136 | 260 | 70 | 4 | 15.0 | 45.0 | 115 | 0.7 | 2.2 | 50 | 4.7 |

| Spanning | 700V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 200 | 76 | 75 | 40 | 15 | 3.0 | 9.0 | 40 | 4 | 3.1 | 32 | 0.5 |

| 400 | 76 | 130 | 45 | 15 | 6.0 | 18.0 | 60 | 2 | 2.8 | 32 | 0.75 |

| 420 | 76 | 130 | 50 | 15 | 6.3 | 18.9 | 60 | 2 | 2.8 | 32 | 0.75 |

| 600 | 86 | 125 | 60 | 15 | 9.0 | 27.0 | 45 | 3.2 | 3.1 | 32 | 1.05 |

| 550 | 86 | 130 | 50 | 12 | 6.6 | 19.8 | 65 | 1.8 | 2.6 | 32 | 1.1 |

| 680 | 96 | 130 | 45 | 12 | 8.2 | 24.5 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 720 | 96 | 125 | 60 | 12 | 8.6 | 25.9 | 55 | 2.6 | 2.5 | 45 | 1.15 |

| 1000 | 116 | 130 | 50 | 10 | 10.0 | 30.0 | 80 | 1 | 3.1 | 50 | 1.6 |

| 1000 | 96 | 180 | 60 | 10 | 10.0 | 30.0 | 75 | 1.2 | 3.0 | 45 | 1.6 |

| 1500 | 116 | 180 | 60 | 7 | 10.5 | 31.5 | 85 | 0.9 | 3.1 | 50 | 2.4 |

| 2000 | 116 | 230 | 70 | 7 | 14.0 | 42.0 | 85 | 0.8 | 3.5 | 50 | 3 |

| 2000 | 136 | 180 | 60 | 7 | 14.0 | 42.0 | 90 | 0.75 | 3.3 | 50 | 3.7 |

| 3000 | 136 | 230 | 70 | 5 | 15.0 | 45.0 | 100 | 0.7 | 2.9 | 50 | 4.2 |

| 3300 | 136 | 260 | 70 | 5 | 16.5 | 49.5 | 120 | 0.6 | 2.3 | 50 | 4.7 |

| Spanning | 800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 110 | 86 | 80 | 45 | 20 | 2.2 | 6.6 | 75 | 2 | 1.8 | 32 | 0.8 |

| 150 | 86 | 95 | 45 | 20 | 3.0 | 9.0 | 80 | 1.5 | 2.1 | 32 | 0.85 |

| 250 | 86 | 75 | 45 | 15 | 3.8 | 11.3 | 45 | 3.1 | 3.2 | 32 | 0.8 |

| 360 | 86 | 130 | 55 | 12 | 4.3 | 13.0 | 65 | 2.2 | 2.2 | 32 | 1.1 |

| 470 | 86 | 130 | 45 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.1 |

| 600 | 96 | 130 | 55 | 10 | 6.0 | 18.0 | 75 | 2.2 | 1.6 | 45 | 1.2 |

| 730 | 86 | 180 | 55 | 10 | 7.3 | 21.9 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 750 | 86 | 180 | 55 | 12 | 9.0 | 27.0 | 75 | 1.8 | 2.0 | 32 | 1.5 |

| 1000 | 96 | 180 | 60 | 10 | 10.0 | 30.0 | 75 | 1.3 | 2.7 | 45 | 1.6 |

| 900 | 116 | 130 | 65 | 7 | 6.3 | 18.9 | 80 | 1.4 | 2.2 | 50 | 1.6 |

| 1400 | 116 | 180 | 65 | 7 | 9.8 | 29.4 | 80 | 0.9 | 3.5 | 50 | 2.4 |

| 1000 | 116 | 125 | 60 | 7 | 7.0 | 21.0 | 70 | 1.4 | 2.9 | 50 | 1.55 |

| 2000 | 116 | 230 | 65 | 5 | 10.0 | 30.0 | 85 | 0.9 | 3.1 | 50 | 3 |

| 2800 | 136 | 230 | 70 | 5 | 14.0 | 42.0 | 100 | 0.8 | 2.5 | 50 | 4.2 |

| Spanning | 900V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 160 | 76 | 75 | 40 | 15 | 3.0 | 9.0 | 35 | 3 | 5.4 | 32 | 0.5 |

| 320 | 76 | 130 | 50 | 15 | 5.0 | 14.9 | 60 | 3.2 | 1.7 | 32 | 0.75 |

| 350 | 76 | 125 | 50 | 15 | 5.0 | 15.0 | 40 | 2.8 | 4.5 | 32 | 0.75 |

| 210 | 86 | 75 | 40 | 15 | 3.2 | 9.5 | 40 | 2.2 | 5.7 | 32 | 0.8 |

| 450 | 86 | 125 | 45 | 12 | 5.4 | 16.2 | 50 | 2.7 | 3.0 | 32 | 1.1 |

| 420 | 86 | 130 | 45 | 12 | 5.0 | 15.1 | 65 | 2.5 | 1.9 | 32 | 1.1 |

| 490 | 86 | 120 | 45 | 10 | 4.9 | 14.7 | 70 | 1.8 | 2.3 | 32 | 1.05 |

| 510 | 86 | 120 | 45 | 10 | 5.1 | 15.3 | 70 | 1.8 | 2.3 | 32 | 1.05 |

| 660 | 86 | 180 | 50 | 10 | 6.6 | 19.8 | 70 | 2 | 2.0 | 32 | 1.5 |

| 900 | 86 | 230 | 50 | 10 | 9.0 | 27.0 | 65 | 2.1 | 2.3 | 32 | 1.8 |

| 580 | 96 | 125 | 50 | 10 | 5.8 | 17.4 | 55 | 3.3 | 2.0 | 45 | 1.2 |

| 540 | 96 | 130 | 50 | 7 | 3.8 | 11.3 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 630 | 116 | 100 | 55 | 7 | 4.4 | 13.2 | 60 | 2 | 2.8 | 50 | 1.3 |

| 860 | 116 | 125 | 55 | 7 | 6.0 | 18.1 | 60 | 2.2 | 2.5 | 50 | 1.55 |

| 810 | 116 | 130 | 60 | 7 | 5.7 | 17.0 | 80 | 1.2 | 2.6 | 50 | 1.6 |

| 1250 | 116 | 180 | 60 | 7 | 8.8 | 26.3 | 80 | 1.2 | 2.6 | 50 | 2.4 |

| 1700 | 116 | 230 | 60 | 5 | 8.5 | 25.5 | 80 | 1.1 | 2.8 | 50 | 3 |

| 1700 | 136 | 180 | 65 | 6 | 10.2 | 30.6 | 100 | 0.9 | 2.2 | 50 | 3.7 |

| 2400 | 136 | 230 | 70 | 5 | 12.0 | 36.0 | 100 | 0.95 | 2.1 | 50 | 4.2 |

| Spanning | 1100V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 130 | 76 | 75 | 40 | 15 | 1.9 | 5.6 | 35 | 4.5 | 3.6 | 32 | 0.5 |

| 260 | 76 | 130 | 45 | 15 | 3.8 | 11.3 | 60 | 2.8 | 2.0 | 32 | 0.75 |

| 280 | 76 | 125 | 50 | 12 | 3.3 | 9.9 | 35 | 4 | 4.1 | 32 | 0.75 |

| 170 | 86 | 75 | 50 | 15 | 2.6 | 7.7 | 45 | 5 | 2.0 | 32 | 0.8 |

| 360 | 86 | 125 | 55 | 12 | 4.3 | 13.0 | 35 | 2.5 | 6.5 | 32 | 1.1 |

| 330 | 86 | 130 | 45 | 15 | 5.0 | 15.0 | 65 | 2.8 | 1.7 | 32 | 1.1 |

| 420 | 86 | 136 | 45 | 12 | 5.0 | 15.0 | 60 | 2 | 2.8 | 32 | 1.15 |

| 420 | 86 | 155 | 45 | 12 | 5.0 | 15.0 | 65 | 1.5 | 3.2 | 32 | 1.25 |

| 470 | 86 | 180 | 60 | 10 | 4.7 | 14.1 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 500 | 86 | 180 | 60 | 10 | 5.0 | 15.0 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 600 | 86 | 225 | 60 | 10 | 6.0 | 18.0 | 80 | 1.2 | 2.6 | 32 | 1.8 |

| 600 | 86 | 225 | 70 | 10 | 6.0 | 18.0 | 60 | 2.2 | 2.5 | 32 | 1.8 |

| 600 | 116 | 130 | 50 | 10 | 6.0 | 18.0 | 75 | 1.8 | 2.0 | 50 | 1.6 |

| 680 | 86 | 225 | 70 | 12 | 8.2 | 24.5 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 720 | 86 | 230 | 70 | 12 | 8.6 | 25.9 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 460 | 96 | 125 | 65 | 10 | 4.6 | 13.8 | 55 | 3.2 | 2.1 | 45 | 1.2 |

| 520 | 96 | 180 | 65 | 12 | 6.2 | 18.7 | 75 | 1.5 | 2.4 | 45 | 1.6 |

| 500 | 116 | 100 | 70 | 10 | 5.0 | 15.0 | 55 | 2.5 | 2.6 | 50 | 1.3 |

| 680 | 116 | 125 | 70 | 10 | 6.8 | 20.4 | 60 | 2.8 | 2.0 | 50 | 1.6 |

| 650 | 116 | 130 | 75 | 10 | 6.5 | 19.5 | 75 | 1.3 | 2.7 | 50 | 1.6 |

| 1000 | 116 | 180 | 75 | 12 | 12.0 | 36.0 | 75 | 1.5 | 2.4 | 50 | 2.4 |

| 1200 | 116 | 230 | 80 | 8 | 9.6 | 28.8 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1200 | 116 | 230 | 75 | 12 | 14.4 | 43.2 | 105 | 0.9 | 2.0 | 50 | 3 |

| 1250 | 116 | 230 | 75 | 12 | 15.0 | 45.0 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1300 | 116 | 230 | 75 | 12 | 15.6 | 46.8 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1400 | 136 | 180 | 70 | 7 | 9.8 | 29.4 | 85 | 1.3 | 2.1 | 50 | 3.7 |

| 1700 | 136 | 230 | 70 | 5 | 8.5 | 25.5 | 100 | 1.4 | 1.4 | 50 | 4.2 |

| 1900 | 136 | 230 | 75 | 5 | 9.5 | 28.5 | 100 | 1.2 | 1.7 | 50 | 4.2 |

| 2800 | 136 | 335 | 80 | 5 | 14.0 | 42.0 | 120 | 0.8 | 1.7 | 50 | 6.1 |

| 3060 | 136 | 345 | 80 | 5 | 15.3 | 45.9 | 120 | 0.9 | 1.5 | 50 | 6.2 |

| 3200 | 136 | 335 | 80 | 5 | 16.0 | 48.0 | 120 | 0.85 | 1.6 | 50 | 6.1 |

| Spanning | 1200V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 170 | 86 | 75 | 50 | 15 | 2.6 | 7.7 | 45 | 4.5 | 2.2 | 32 | 0.8 |

| 420 | 76 | 145 | 50 | 15 | 6.3 | 18.9 | 30 | 12 | 1.9 | 32 | 0.85 |

| 330 | 86 | 130 | 45 | 15 | 5.0 | 15.0 | 65 | 2.8 | 1.7 | 32 | 1.1 |

| 420 | 86 | 136 | 45 | 12 | 5.0 | 15.0 | 65 | 2 | 2.4 | 32 | 1.15 |

| 420 | 86 | 155 | 45 | 12 | 5.0 | 15.0 | 70 | 1.5 | 2.7 | 32 | 1.25 |

| 420 | 116 | 95 | 55 | 10 | 4.2 | 12.6 | 80 | 1.4 | 2.2 | 50 | 1.2 |

| 450 | 86 | 160 | 55 | 12 | 5.4 | 16.2 | 70 | 2.9 | 1.4 | 32 | 1.3 |

| 470 | 86 | 180 | 60 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.5 |

| 470 | 86 | 225 | 60 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.8 |

| 550 | 86 | 145 | 55 | 12 | 6.6 | 19.8 | 40 | 11 | 1.1 | 32 | 1,2 |

| 600 | 86 | 225 | 60 | 10 | 6.0 | 18.0 | 80 | 1.2 | 2.6 | 32 | 1.8 |

| 600 | 86 | 225 | 70 | 10 | 6.0 | 18.0 | 60 | 2.2 | 2.5 | 32 | 1.8 |

| 600 | 116 | 130 | 50 | 10 | 6.0 | 18.0 | 75 | 1.8 | 2.0 | 50 | 1.6 |

| 680 | 86 | 225 | 70 | 12 | 8.2 | 24.5 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 500 | 116 | 100 | 65 | 10 | 5.0 | 15.0 | 55 | 2.6 | 2.5 | 50 | 1.2 |

| 680 | 116 | 125 | 65 | 10 | 6.8 | 20.4 | 50 | 2.8 | 2.9 | 50 | 1.55 |

| 650 | 116 | 130 | 65 | 10 | 6.5 | 19.5 | 80 | 1.8 | 1.7 | 50 | 1.6 |

| 1000 | 116 | 180 | 70 | 7 | 7.0 | 21.0 | 75 | 1.3 | 2.7 | 50 | 2.4 |

| 1200 | 116 | 230 | 70 | 7 | 8.4 | 25.2 | 75 | 1.3 | 2.7 | 50 | 3 |

| 1250 | 116 | 230 | 70 | 7 | 8.8 | 26.3 | 75 | 1.2 | 3.0 | 50 | 3 |

| 1400 | 136 | 180 | 75 | 7 | 9.8 | 29.4 | 85 | 1.1 | 2.5 | 50 | 3.7 |

| 1700 | 136 | 230 | 80 | 5 | 8.5 | 25.5 | 85 | 1 | 2.8 | 50 | 4.2 |

| 850 | 136 | 125 | 70 | 8 | 6.8 | 20.4 | 75 | 1.6 | 2.2 | 50 | 1.9 |

| 950 | 136 | 125 | 60 | 8 | 7.6 | 22.8 | 80 | 1.1 | 2.8 | 50 | 2.4 |

| 1200 | 116 | 180 | 80 | 8 | 9.6 | 28.8 | 80 | 1 | 3.1 | 50 | 2.4 |

| 1200 | 116 | 180 | 60 | 5 | 6.0 | 18.0 | 100 | 0.8 | 2.5 | 50 | 2.4 |

| 1500 | 136 | 180 | 70 | 5 | 7.5 | 22.5 | 100 | 0.9 | 2.2 | 50 | 3.7 |

| 2700 | 136 | 335 | 80 | 5 | 13.5 | 40.5 | 110 | 0.85 | 1.9 | 50 | 6.1 |

| Spanning | 1300V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 230 | 86 | 125 | 50 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 210 | 86 | 130 | 50 | 15 | 3.2 | 9.5 | 70 | 2 | 2.0 | 32 | 1.1 |

| 330 | 86 | 180 | 60 | 15 | 5.0 | 14.9 | 65 | 3 | 1.6 | 32 | 1.5 |

| 470 | 86 | 230 | 65 | 12 | 5.6 | 16.9 | 65 | 3.2 | 1.5 | 32 | 1.8 |

| 410 | 116 | 130 | 65 | 12 | 4.9 | 14.8 | 80 | 1.8 | 1.7 | 50 | 1.6 |

| 650 | 116 | 180 | 65 | 10 | 6.5 | 19.5 | 85 | 2 | 1.4 | 50 | 2.4 |

| 880 | 116 | 230 | 80 | 10 | 8.8 | 26.4 | 85 | 2.2 | 1.3 | 50 | 3 |

| 900 | 136 | 180 | 70 | 7 | 6.3 | 18.9 | 100 | 1.6 | 1.3 | 50 | 3.7 |

| 1200 | 136 | 230 | 80 | 7 | 8.4 | 25.2 | 105 | 1.5 | 1.2 | 50 | 4.2 |

| Spanning | 1500V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 160 | 86 | 125 | 50 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 160 | 86 | 130 | 50 | 15 | 2.4 | 7.2 | 60 | 3.5 | 1.6 | 32 | 1.1 |

| 240 | 86 | 180 | 55 | 15 | 3.6 | 10.8 | 65 | 5 | 0.9 | 32 | 1.5 |

| 320 | 86 | 230 | 55 | 12 | 3.8 | 11.5 | 60 | 3.5 | 1.6 | 32 | 1.8 |

| 300 | 116 | 130 | 55 | 12 | 3.6 | 10.8 | 75 | 2 | 1.8 | 50 | 1.6 |

| 470 | 116 | 180 | 60 | 10 | 4.7 | 14.1 | 75 | 2.8 | 1.3 | 50 | 2.4 |

| 650 | 116 | 230 | 60 | 10 | 6.5 | 19.5 | 80 | 2.8 | 1.1 | 50 | 3 |

| 660 | 136 | 180 | 60 | 7 | 4.6 | 13.9 | 100 | 1.8 | 1.1 | 50 | 3.7 |

| 900 | 136 | 230 | 60 | 6 | 5.4 | 16.2 | 105 | 1.2 | 1.5 | 50 | 4.2 |

| 1000 | 136 | 260 | 70 | 5 | 5.0 | 15.0 | 120 | 0.9 | 1.5 | 50 | 4.7 |

| Spanning | 1800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 130 | 86 | 125 | 55 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 120 | 86 | 130 | 55 | 15 | 1.8 | 5.4 | 60 | 2.5 | 2.2 | 32 | 1.1 |

| 180 | 86 | 180 | 60 | 15 | 2.7 | 8.1 | 65 | 2 | 2.4 | 32 | 1.5 |

| 260 | 86 | 230 | 60 | 12 | 3.1 | 9.4 | 60 | 3 | 1.9 | 32 | 1.8 |

| 230 | 116 | 130 | 60 | 12 | 2.8 | 8.3 | 80 | 2 | 1.6 | 50 | 1.6 |

| 360 | 116 | 180 | 65 | 10 | 3.6 | 10.8 | 80 | 3.2 | 1.0 | 50 | 2.4 |

| 500 | 116 | 230 | 70 | 10 | 5.0 | 15.0 | 75 | 3 | 1.2 | 50 | 3 |

| 510 | 136 | 180 | 70 | 7 | 3.6 | 10.7 | 100 | 2 | 1.0 | 50 | 3.7 |

| 680 | 136 | 230 | 70 | 7 | 4.8 | 14.3 | 95 | 2 | 1.1 | 50 | 4.2 |

| Spanning | 2000V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 100 | 86 | 125 | 55 | 15 | 1.5 | 4.5 | 35 | 3.8 | 4.3 | 32 | 1.1 |

| 90 | 86 | 130 | 55 | 15 | 1.4 | 4.1 | 65 | 2.5 | 1.9 | 32 | 1.1 |

| 150 | 86 | 180 | 60 | 15 | 2.3 | 6.8 | 60 | 3.5 | 1.6 | 32 | 1.5 |

| 200 | 86 | 230 | 60 | 12 | 2.4 | 7.2 | 65 | 2 | 2.4 | 32 | 1.8 |

| 180 | 116 | 130 | 65 | 10 | 1.8 | 5.4 | 75 | 2.5 | 1.4 | 50 | 1.6 |

| 280 | 116 | 180 | 70 | 10 | 2.8 | 8.4 | 70 | 2 | 2.0 | 50 | 2.4 |

| 380 | 116 | 230 | 80 | 10 | 3.8 | 11.4 | 80 | 2 | 1.6 | 50 | 3 |

| 400 | 136 | 180 | 60 | 7 | 2.8 | 8.4 | 100 | 1.6 | 1.3 | 50 | 3.7 |

| 550 | 136 | 230 | 70 | 7 | 3.9 | 11.6 | 100 | 1.5 | 1.3 | 50 | 4.2 |

| 850 | 136 | 335 | 80 | 5 | 4.3 | 12.8 | 120 | 1.1 | 1.3 | 50 | 6.1 |

| Spanning | 2800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 160 | 116 | 180 | 70 | 30 | 4.8 | 14.4 | 75 | 2.2 | 1.6 | 50 | 2.4 |

| 210 | 116 | 230 | 75 | 25 | 5.3 | 15.8 | 70 | 2.8 | 1.5 | 50 | 3 |

| 225 | 136 | 180 | 75 | 20 | 4.5 | 13.5 | 85 | 2 | 1.4 | 50 | 3.7 |

| 300 | 136 | 230 | 80 | 15 | 4.5 | 13.5 | 80 | 2.5 | 1.3 | 50 | 4.2 |

| Spanning | 4000V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 70 | 116 | 180 | 70 | 50 | 3.5 | 10.5 | 70 | 3.5 | 1.2 | 50 | 2.4 |

| 95 | 116 | 230 | 75 | 40 | 3.8 | 11.4 | 70 | 3.6 | 1.1 | 50 | 3 |

| 100 | 136 | 180 | 75 | 35 | 3.5 | 10.5 | 85 | 3 | 0.9 | 50 | 3.7 |

| 135 | 136 | 230 | 80 | 30 | 4.1 | 12.2 | 80 | 3.5 | 0.9 | 50 | 4.2 |

Produk detail foto's:

Verwante produkgids:

Ons streef na die bestuursbeginsel van "Kwaliteit is superieur, diens is oppermagtig, reputasie is eerste", en sal opreg sukses skep en deel met alle kliënte vir Gewilde Ontwerp vir Gemetalliseerde Filmkondensatoroplossing - Hoëspanning selfgenesende filmkondensator in elektroniese en elektriese toestelle - CRE. Die produk sal aan die hele wêreld verskaf word, soos: Egipte, Sacramento, Costa Rica. Al ons produkte voldoen aan internasionale kwaliteitsstandaarde en word baie waardeer in 'n verskeidenheid markte regoor die wêreld. As u belangstel in enige van ons produkte of 'n persoonlike bestelling wil bespreek, kontak ons gerus. Ons sien uit daarna om suksesvolle sakeverhoudings met nuwe kliënte in die nabye toekoms te vorm.

Verkoopbestuurder is baie entoesiasties en professioneel, het ons 'n goeie toegewing gegee en die produkgehalte is baie goed, baie dankie!