Kragelektroniese filmkondensator wat gebruik word vir kragomskakeling

Ons het nou 'n kundige, doeltreffende personeel om hoë kwaliteit verskaffers aan ons kliënte te lewer. Ons volg gewoonlik die beginsel van kliëntgerigte, detail-gefokusde kragelektroniese filmkondensators wat vir kragomskakeling gebruik word. Ons hoop opreg om op die lange duur bevredigende interaksies met u te bewerkstellig. Ons sal u op hoogte hou van ons vordering en op hoogte bly van die bou van bestendige sakeverhoudings met u.

Ons het nou kundige, doeltreffende personeel om hoë kwaliteit verskaffers aan ons kliënte te lewer. Ons volg gewoonlik die beginsel van kliëntgerigte, detail-gefokusdekragfilmkondensatorMeer as 26 jaar lank beskou professionele maatskappye van oor die hele wêreld ons as hul langtermyn- en stabiele vennote. Ons handhaaf duursame sakeverhoudings met meer as 200 groothandelaars in Japan, Korea, VSA, VK, Duitsland, Kanada, Frankryk, Italië, Pole, Suid-Afrika, Ghana, Nigerië, ens.

Tegniese data

| Bedryfstemperatuurreeks | Maks. Bedryfstemperatuur., Top, maks: +85 ℃ Boonste kategorie temperatuur: +70 ℃ Laer kategorie temperatuur: -40 ℃ | |

| kapasitansiebereik | 50μF~4000μF | |

| Gegradeerde spanning | 450V.GS~4000V.GS | |

| Kapasitansie-toleransie | ±5%(J);±10%(K) | |

| Weerstaan spanning | Vt-t | 1.5Un GS/60S |

| Vt-c | 1000+2×Un/√2 (V.AC) 60S (min3000 V.AC) | |

| Oorspanning | 1.1Un(30% van die duur van die lading) | |

| 1.15Un(30min/dag) | ||

| 1.2Un(5min/dag) | ||

| 1.3Un(1min/dag) | ||

| 1.5Un (100ms elke keer, 1000 keer gedurende die leeftyd) | ||

| Dissipasiefaktor | tgδ≤0.003 f=100Hz | |

| tgδ0≤0.0002 | ||

| Isolasieweerstand | Rs*C≥10000S (teen 20℃ 100V.DC 60s) | |

| Vlamvertraging | UL94V-0 | |

| Maksimum vermoë | 3500m | |

| Wanneer die hoogte bo 3500m tot binne 5500m is, is dit nodig om die gebruik van 'n verminderde hoeveelheid te oorweeg. (vir elke toename van 1000m sal die spanning en stroom met 10% verminder word). | ||

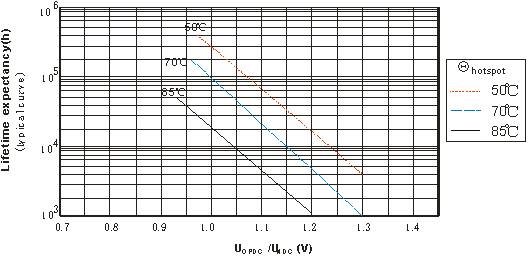

| Lewensverwagting | 100 000h(Un; Θhotspot≤70 °C) | |

| Verwysingsstandaard | IEC61071 ;GB/T17702; | |

Kenmerk

1. Gemetalliseerde plastiekfilm;

2. Kompakte ontwerp;

3. Droë-tipe tegnologie;

4. Selfgenesing;

5. Lae verlies, lang lewensduur;

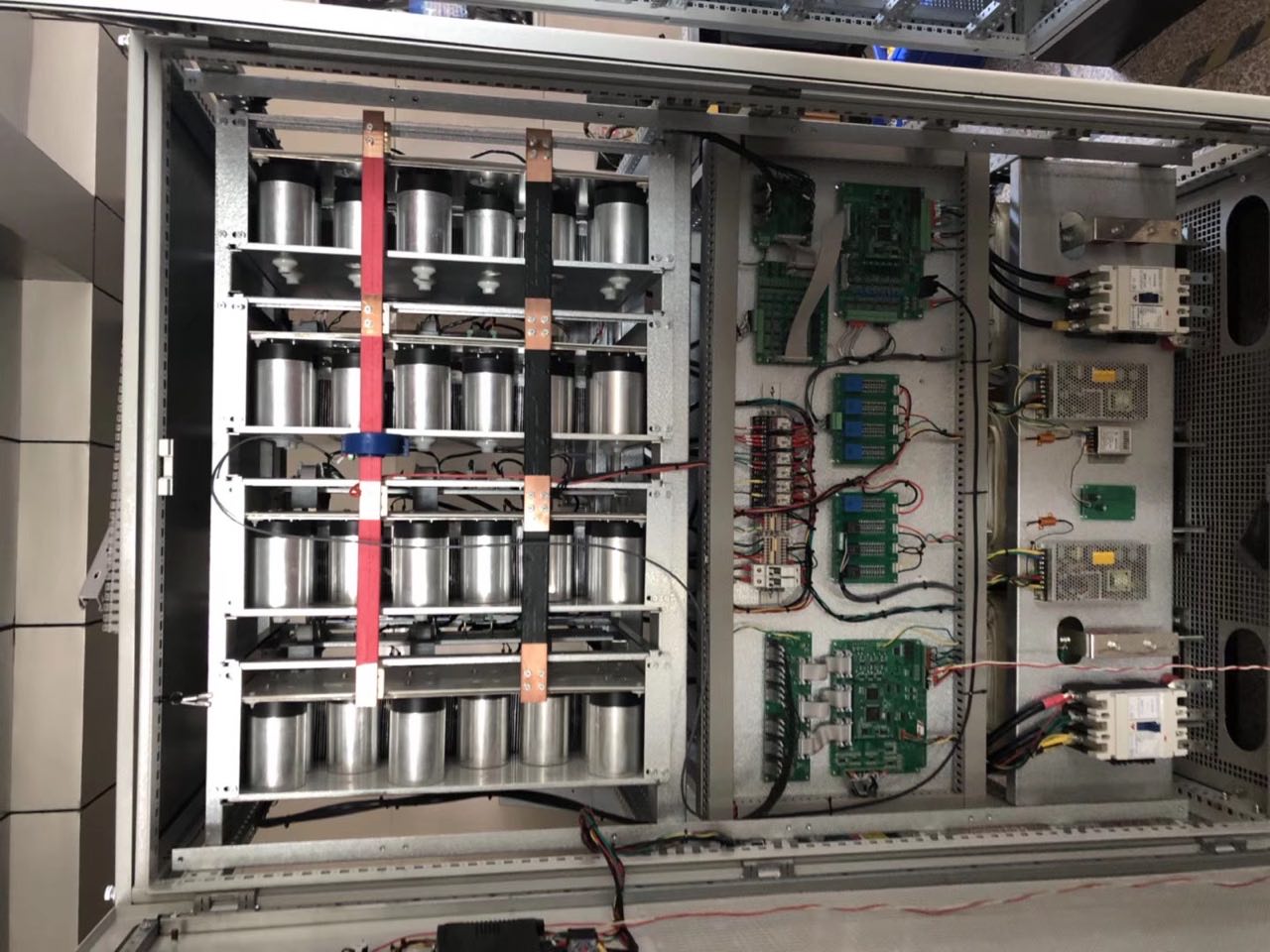

Toepassing

1. Kragomskakelaar;

2. Aktiewe kragfilter;

3. EV- en HEV-motor;

4. Laaitoestel;

5. Mediese toestelle;

6. Industriële outomatisering;

Lewensverwagting

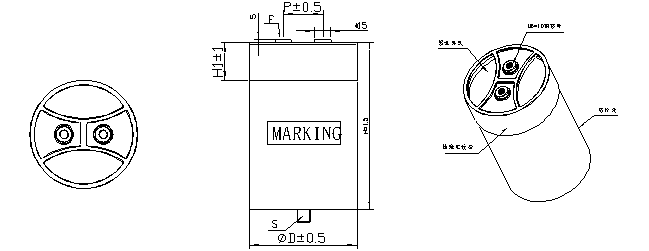

Oorsigtekening

| ΦD(mm) | P(mm) | H1(mm) | S | F | M |

| 76 | 32 | 20 | M12×16 | M6×10 | M8×20 |

| 86 | 32 | 20 | M12×16 | M6×10 | M8×20 |

| 96 | 45 | 20 | M12×16 | M6×10 | M8×20 |

| 116 | 50 | 22 | M12×16 | M6×10 | M8×20 |

| 136 | 50 | 30 | M16×25 | M6×10 | M8×20 |

| Spanning | 450V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 380 | 76 | 75 | 50 | 10 | 3.8 | 11.4 | 45 | 2.2 | 4.5 | 32 | 0.5 |

| 500 | 76 | 100 | 40 | 8 | 4.0 | 12.0 | 65 | 1.5 | 3.2 | 32 | 0.6 |

| 750 | 76 | 130 | 50 | 5 | 3.8 | 11.3 | 65 | 1.6 | 3.0 | 32 | 0.75 |

| 500 | 86 | 75 | 50 | 8 | 4.0 | 12.0 | 55 | 1.8 | 3.7 | 32 | 0.8 |

| 1000 | 86 | 130 | 50 | 5 | 5.0 | 15.0 | 70 | 1.5 | 2.7 | 32 | 1.1 |

| 650 | 86 | 100 | 40 | 5 | 3.3 | 9.8 | 75 | 1.2 | 3.0 | 32 | 0.9 |

| 650 | 86 | 95 | 40 | 5 | 3.3 | 9.8 | 75 | 1.2 | 3.0 | 32 | 0.85 |

| 650 | 96 | 75 | 50 | 5 | 3.3 | 9.8 | 60 | 1.5 | 3.7 | 45 | 0.75 |

| 1250 | 96 | 130 | 50 | 4 | 5.0 | 15.0 | 80 | 1 | 3.1 | 45 | 1.2 |

| 1800 | 116 | 130 | 50 | 4 | 7.2 | 21.6 | 85 | 0.8 | 3.5 | 50 | 1.6 |

| 1450 | 86 | 190 | 60 | 4 | 5.8 | 17.4 | 90 | 0.9 | 2.7 | 32 | 1.55 |

| 2700 | 116 | 190 | 60 | 3 | 8.1 | 24.3 | 100 | 0.8 | 2.5 | 50 | 2.45 |

| Spanning | 600V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 250 | 76 | 75 | 40 | 15 | 3.8 | 11.3 | 40 | 3.1 | 4.0 | 32 | 0.5 |

| 320 | 76 | 100 | 40 | 10 | 3.2 | 9.6 | 40 | 2.2 | 5.7 | 32 | 0.6 |

| 470 | 76 | 130 | 45 | 12 | 5.6 | 16.9 | 60 | 1.8 | 3.1 | 32 | 0.75 |

| 330 | 86 | 75 | 40 | 15 | 5.0 | 14.9 | 45 | 2.4 | 4.1 | 32 | 0.8 |

| 600 | 86 | 120 | 45 | 12 | 7.2 | 21.6 | 60 | 1.3 | 4.3 | 32 | 1.05 |

| 650 | 86 | 130 | 50 | 12 | 7.8 | 23.4 | 70 | 1.2 | 3.4 | 32 | 1.1 |

| 650 | 86 | 95 | 50 | 15 | 9.8 | 29.3 | 65 | 1.2 | 3.9 | 32 | 0.85 |

| 1000 | 86 | 180 | 50 | 12 | 12.0 | 36.0 | 70 | 1.5 | 2.7 | 32 | 1.5 |

| 420 | 96 | 75 | 45 | 15 | 6.3 | 18.9 | 50 | 2 | 4.0 | 45 | 0.75 |

| 800 | 96 | 130 | 60 | 12 | 9.6 | 28.8 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 950 | 116 | 100 | 60 | 10 | 9.5 | 28.5 | 90 | 1.2 | 2.1 | 50 | 1.25 |

| 1200 | 116 | 130 | 70 | 8 | 9.6 | 28.8 | 80 | 1.2 | 2.6 | 50 | 1.6 |

| 1800 | 116 | 180 | 50 | 8 | 14.4 | 43.2 | 80 | 1.2 | 2.6 | 50 | 2.4 |

| 2700 | 116 | 260 | 70 | 5 | 13.5 | 40.5 | 100 | 0.9 | 2.2 | 50 | 3.2 |

| 2500 | 136 | 180 | 60 | 5 | 12.5 | 37.5 | 100 | 0.8 | 2.5 | 50 | 3.7 |

| 3750 | 136 | 260 | 70 | 4 | 15.0 | 45.0 | 115 | 0.7 | 2.2 | 50 | 4.7 |

| Spanning | 700V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 200 | 76 | 75 | 40 | 15 | 3.0 | 9.0 | 40 | 4 | 3.1 | 32 | 0.5 |

| 400 | 76 | 130 | 45 | 15 | 6.0 | 18.0 | 60 | 2 | 2.8 | 32 | 0.75 |

| 420 | 76 | 130 | 50 | 15 | 6.3 | 18.9 | 60 | 2 | 2.8 | 32 | 0.75 |

| 600 | 86 | 125 | 60 | 15 | 9.0 | 27.0 | 45 | 3.2 | 3.1 | 32 | 1.05 |

| 550 | 86 | 130 | 50 | 12 | 6.6 | 19.8 | 65 | 1.8 | 2.6 | 32 | 1.1 |

| 680 | 96 | 130 | 45 | 12 | 8.2 | 24.5 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 720 | 96 | 125 | 60 | 12 | 8.6 | 25.9 | 55 | 2.6 | 2.5 | 45 | 1.15 |

| 1000 | 116 | 130 | 50 | 10 | 10.0 | 30.0 | 80 | 1 | 3.1 | 50 | 1.6 |

| 1000 | 96 | 180 | 60 | 10 | 10.0 | 30.0 | 75 | 1.2 | 3.0 | 45 | 1.6 |

| 1500 | 116 | 180 | 60 | 7 | 10.5 | 31.5 | 85 | 0.9 | 3.1 | 50 | 2.4 |

| 2000 | 116 | 230 | 70 | 7 | 14.0 | 42.0 | 85 | 0.8 | 3.5 | 50 | 3 |

| 2000 | 136 | 180 | 60 | 7 | 14.0 | 42.0 | 90 | 0.75 | 3.3 | 50 | 3.7 |

| 3000 | 136 | 230 | 70 | 5 | 15.0 | 45.0 | 100 | 0.7 | 2.9 | 50 | 4.2 |

| 3300 | 136 | 260 | 70 | 5 | 16.5 | 49.5 | 120 | 0.6 | 2.3 | 50 | 4.7 |

| Spanning | 800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 110 | 86 | 80 | 45 | 20 | 2.2 | 6.6 | 75 | 2 | 1.8 | 32 | 0.8 |

| 150 | 86 | 95 | 45 | 20 | 3.0 | 9.0 | 80 | 1.5 | 2.1 | 32 | 0.85 |

| 250 | 86 | 75 | 45 | 15 | 3.8 | 11.3 | 45 | 3.1 | 3.2 | 32 | 0.8 |

| 360 | 86 | 130 | 55 | 12 | 4.3 | 13.0 | 65 | 2.2 | 2.2 | 32 | 1.1 |

| 470 | 86 | 130 | 45 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.1 |

| 600 | 96 | 130 | 55 | 10 | 6.0 | 18.0 | 75 | 2.2 | 1.6 | 45 | 1.2 |

| 730 | 86 | 180 | 55 | 10 | 7.3 | 21.9 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 750 | 86 | 180 | 55 | 12 | 9.0 | 27.0 | 75 | 1.8 | 2.0 | 32 | 1.5 |

| 1000 | 96 | 180 | 60 | 10 | 10.0 | 30.0 | 75 | 1.3 | 2.7 | 45 | 1.6 |

| 900 | 116 | 130 | 65 | 7 | 6.3 | 18.9 | 80 | 1.4 | 2.2 | 50 | 1.6 |

| 1400 | 116 | 180 | 65 | 7 | 9.8 | 29.4 | 80 | 0.9 | 3.5 | 50 | 2.4 |

| 1000 | 116 | 125 | 60 | 7 | 7.0 | 21.0 | 70 | 1.4 | 2.9 | 50 | 1.55 |

| 2000 | 116 | 230 | 65 | 5 | 10.0 | 30.0 | 85 | 0.9 | 3.1 | 50 | 3 |

| 2800 | 136 | 230 | 70 | 5 | 14.0 | 42.0 | 100 | 0.8 | 2.5 | 50 | 4.2 |

| Spanning | 900V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 160 | 76 | 75 | 40 | 15 | 3.0 | 9.0 | 35 | 3 | 5.4 | 32 | 0.5 |

| 320 | 76 | 130 | 50 | 15 | 5.0 | 14.9 | 60 | 3.2 | 1.7 | 32 | 0.75 |

| 350 | 76 | 125 | 50 | 15 | 5.0 | 15.0 | 40 | 2.8 | 4.5 | 32 | 0.75 |

| 210 | 86 | 75 | 40 | 15 | 3.2 | 9.5 | 40 | 2.2 | 5.7 | 32 | 0.8 |

| 450 | 86 | 125 | 45 | 12 | 5.4 | 16.2 | 50 | 2.7 | 3.0 | 32 | 1.1 |

| 420 | 86 | 130 | 45 | 12 | 5.0 | 15.1 | 65 | 2.5 | 1.9 | 32 | 1.1 |

| 490 | 86 | 120 | 45 | 10 | 4.9 | 14.7 | 70 | 1.8 | 2.3 | 32 | 1.05 |

| 510 | 86 | 120 | 45 | 10 | 5.1 | 15.3 | 70 | 1.8 | 2.3 | 32 | 1.05 |

| 660 | 86 | 180 | 50 | 10 | 6.6 | 19.8 | 70 | 2 | 2.0 | 32 | 1.5 |

| 900 | 86 | 230 | 50 | 10 | 9.0 | 27.0 | 65 | 2.1 | 2.3 | 32 | 1.8 |

| 580 | 96 | 125 | 50 | 10 | 5.8 | 17.4 | 55 | 3.3 | 2.0 | 45 | 1.2 |

| 540 | 96 | 130 | 50 | 7 | 3.8 | 11.3 | 75 | 1.5 | 2.4 | 45 | 1.2 |

| 630 | 116 | 100 | 55 | 7 | 4.4 | 13.2 | 60 | 2 | 2.8 | 50 | 1.3 |

| 860 | 116 | 125 | 55 | 7 | 6.0 | 18.1 | 60 | 2.2 | 2.5 | 50 | 1.55 |

| 810 | 116 | 130 | 60 | 7 | 5.7 | 17.0 | 80 | 1.2 | 2.6 | 50 | 1.6 |

| 1250 | 116 | 180 | 60 | 7 | 8.8 | 26.3 | 80 | 1.2 | 2.6 | 50 | 2.4 |

| 1700 | 116 | 230 | 60 | 5 | 8.5 | 25.5 | 80 | 1.1 | 2.8 | 50 | 3 |

| 1700 | 136 | 180 | 65 | 6 | 10.2 | 30.6 | 100 | 0.9 | 2.2 | 50 | 3.7 |

| 2400 | 136 | 230 | 70 | 5 | 12.0 | 36.0 | 100 | 0.95 | 2.1 | 50 | 4.2 |

| Spanning | 1100V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 130 | 76 | 75 | 40 | 15 | 1.9 | 5.6 | 35 | 4.5 | 3.6 | 32 | 0.5 |

| 260 | 76 | 130 | 45 | 15 | 3.8 | 11.3 | 60 | 2.8 | 2.0 | 32 | 0.75 |

| 280 | 76 | 125 | 50 | 12 | 3.3 | 9.9 | 35 | 4 | 4.1 | 32 | 0.75 |

| 170 | 86 | 75 | 50 | 15 | 2.6 | 7.7 | 45 | 5 | 2.0 | 32 | 0.8 |

| 360 | 86 | 125 | 55 | 12 | 4.3 | 13.0 | 35 | 2.5 | 6.5 | 32 | 1.1 |

| 330 | 86 | 130 | 45 | 15 | 5.0 | 15.0 | 65 | 2.8 | 1.7 | 32 | 1.1 |

| 420 | 86 | 136 | 45 | 12 | 5.0 | 15.0 | 60 | 2 | 2.8 | 32 | 1.15 |

| 420 | 86 | 155 | 45 | 12 | 5.0 | 15.0 | 65 | 1.5 | 3.2 | 32 | 1.25 |

| 470 | 86 | 180 | 60 | 10 | 4.7 | 14.1 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 500 | 86 | 180 | 60 | 10 | 5.0 | 15.0 | 70 | 1.8 | 2.3 | 32 | 1.5 |

| 600 | 86 | 225 | 60 | 10 | 6.0 | 18.0 | 80 | 1.2 | 2.6 | 32 | 1.8 |

| 600 | 86 | 225 | 70 | 10 | 6.0 | 18.0 | 60 | 2.2 | 2.5 | 32 | 1.8 |

| 600 | 116 | 130 | 50 | 10 | 6.0 | 18.0 | 75 | 1.8 | 2.0 | 50 | 1.6 |

| 680 | 86 | 225 | 70 | 12 | 8.2 | 24.5 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 720 | 86 | 230 | 70 | 12 | 8.6 | 25.9 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 460 | 96 | 125 | 65 | 10 | 4.6 | 13.8 | 55 | 3.2 | 2.1 | 45 | 1.2 |

| 520 | 96 | 180 | 65 | 12 | 6.2 | 18.7 | 75 | 1.5 | 2.4 | 45 | 1.6 |

| 500 | 116 | 100 | 70 | 10 | 5.0 | 15.0 | 55 | 2.5 | 2.6 | 50 | 1.3 |

| 680 | 116 | 125 | 70 | 10 | 6.8 | 20.4 | 60 | 2.8 | 2.0 | 50 | 1.6 |

| 650 | 116 | 130 | 75 | 10 | 6.5 | 19.5 | 75 | 1.3 | 2.7 | 50 | 1.6 |

| 1000 | 116 | 180 | 75 | 12 | 12.0 | 36.0 | 75 | 1.5 | 2.4 | 50 | 2.4 |

| 1200 | 116 | 230 | 80 | 8 | 9.6 | 28.8 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1200 | 116 | 230 | 75 | 12 | 14.4 | 43.2 | 105 | 0.9 | 2.0 | 50 | 3 |

| 1250 | 116 | 230 | 75 | 12 | 15.0 | 45.0 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1300 | 116 | 230 | 75 | 12 | 15.6 | 46.8 | 80 | 1.5 | 2.1 | 50 | 3 |

| 1400 | 136 | 180 | 70 | 7 | 9.8 | 29.4 | 85 | 1.3 | 2.1 | 50 | 3.7 |

| 1700 | 136 | 230 | 70 | 5 | 8.5 | 25.5 | 100 | 1.4 | 1.4 | 50 | 4.2 |

| 1900 | 136 | 230 | 75 | 5 | 9.5 | 28.5 | 100 | 1.2 | 1.7 | 50 | 4.2 |

| 2800 | 136 | 335 | 80 | 5 | 14.0 | 42.0 | 120 | 0.8 | 1.7 | 50 | 6.1 |

| 3060 | 136 | 345 | 80 | 5 | 15.3 | 45.9 | 120 | 0.9 | 1.5 | 50 | 6.2 |

| 3200 | 136 | 335 | 80 | 5 | 16.0 | 48.0 | 120 | 0.85 | 1.6 | 50 | 6.1 |

| Spanning | 1200V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig (kg) |

| 170 | 86 | 75 | 50 | 15 | 2.6 | 7.7 | 45 | 4.5 | 2.2 | 32 | 0.8 |

| 420 | 76 | 145 | 50 | 15 | 6.3 | 18.9 | 30 | 12 | 1.9 | 32 | 0.85 |

| 330 | 86 | 130 | 45 | 15 | 5.0 | 15.0 | 65 | 2.8 | 1.7 | 32 | 1.1 |

| 420 | 86 | 136 | 45 | 12 | 5.0 | 15.0 | 65 | 2 | 2.4 | 32 | 1.15 |

| 420 | 86 | 155 | 45 | 12 | 5.0 | 15.0 | 70 | 1.5 | 2.7 | 32 | 1.25 |

| 420 | 116 | 95 | 55 | 10 | 4.2 | 12.6 | 80 | 1.4 | 2.2 | 50 | 1.2 |

| 450 | 86 | 160 | 55 | 12 | 5.4 | 16.2 | 70 | 2.9 | 1.4 | 32 | 1.3 |

| 470 | 86 | 180 | 60 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.5 |

| 470 | 86 | 225 | 60 | 12 | 5.6 | 16.9 | 70 | 2.8 | 1.5 | 32 | 1.8 |

| 550 | 86 | 145 | 55 | 12 | 6.6 | 19.8 | 40 | 11 | 1.1 | 32 | 1,2 |

| 600 | 86 | 225 | 60 | 10 | 6.0 | 18.0 | 80 | 1.2 | 2.6 | 32 | 1.8 |

| 600 | 86 | 225 | 70 | 10 | 6.0 | 18.0 | 60 | 2.2 | 2.5 | 32 | 1.8 |

| 600 | 116 | 130 | 50 | 10 | 6.0 | 18.0 | 75 | 1.8 | 2.0 | 50 | 1.6 |

| 680 | 86 | 225 | 70 | 12 | 8.2 | 24.5 | 65 | 2.5 | 1.9 | 32 | 1.8 |

| 500 | 116 | 100 | 65 | 10 | 5.0 | 15.0 | 55 | 2.6 | 2.5 | 50 | 1.2 |

| 680 | 116 | 125 | 65 | 10 | 6.8 | 20.4 | 50 | 2.8 | 2.9 | 50 | 1.55 |

| 650 | 116 | 130 | 65 | 10 | 6.5 | 19.5 | 80 | 1.8 | 1.7 | 50 | 1.6 |

| 1000 | 116 | 180 | 70 | 7 | 7.0 | 21.0 | 75 | 1.3 | 2.7 | 50 | 2.4 |

| 1200 | 116 | 230 | 70 | 7 | 8.4 | 25.2 | 75 | 1.3 | 2.7 | 50 | 3 |

| 1250 | 116 | 230 | 70 | 7 | 8.8 | 26.3 | 75 | 1.2 | 3.0 | 50 | 3 |

| 1400 | 136 | 180 | 75 | 7 | 9.8 | 29.4 | 85 | 1.1 | 2.5 | 50 | 3.7 |

| 1700 | 136 | 230 | 80 | 5 | 8.5 | 25.5 | 85 | 1 | 2.8 | 50 | 4.2 |

| 850 | 136 | 125 | 70 | 8 | 6.8 | 20.4 | 75 | 1.6 | 2.2 | 50 | 1.9 |

| 950 | 136 | 125 | 60 | 8 | 7.6 | 22.8 | 80 | 1.1 | 2.8 | 50 | 2.4 |

| 1200 | 116 | 180 | 80 | 8 | 9.6 | 28.8 | 80 | 1 | 3.1 | 50 | 2.4 |

| 1200 | 116 | 180 | 60 | 5 | 6.0 | 18.0 | 100 | 0.8 | 2.5 | 50 | 2.4 |

| 1500 | 136 | 180 | 70 | 5 | 7.5 | 22.5 | 100 | 0.9 | 2.2 | 50 | 3.7 |

| 2700 | 136 | 335 | 80 | 5 | 13.5 | 40.5 | 110 | 0.85 | 1.9 | 50 | 6.1 |

| Spanning | 1300V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 230 | 86 | 125 | 50 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 210 | 86 | 130 | 50 | 15 | 3.2 | 9.5 | 70 | 2 | 2.0 | 32 | 1.1 |

| 330 | 86 | 180 | 60 | 15 | 5.0 | 14.9 | 65 | 3 | 1.6 | 32 | 1.5 |

| 470 | 86 | 230 | 65 | 12 | 5.6 | 16.9 | 65 | 3.2 | 1.5 | 32 | 1.8 |

| 410 | 116 | 130 | 65 | 12 | 4.9 | 14.8 | 80 | 1.8 | 1.7 | 50 | 1.6 |

| 650 | 116 | 180 | 65 | 10 | 6.5 | 19.5 | 85 | 2 | 1.4 | 50 | 2.4 |

| 880 | 116 | 230 | 80 | 10 | 8.8 | 26.4 | 85 | 2.2 | 1.3 | 50 | 3 |

| 900 | 136 | 180 | 70 | 7 | 6.3 | 18.9 | 100 | 1.6 | 1.3 | 50 | 3.7 |

| 1200 | 136 | 230 | 80 | 7 | 8.4 | 25.2 | 105 | 1.5 | 1.2 | 50 | 4.2 |

| Spanning | 1500V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 160 | 86 | 125 | 50 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 160 | 86 | 130 | 50 | 15 | 2.4 | 7.2 | 60 | 3.5 | 1.6 | 32 | 1.1 |

| 240 | 86 | 180 | 55 | 15 | 3.6 | 10.8 | 65 | 5 | 0.9 | 32 | 1.5 |

| 320 | 86 | 230 | 55 | 12 | 3.8 | 11.5 | 60 | 3.5 | 1.6 | 32 | 1.8 |

| 300 | 116 | 130 | 55 | 12 | 3.6 | 10.8 | 75 | 2 | 1.8 | 50 | 1.6 |

| 470 | 116 | 180 | 60 | 10 | 4.7 | 14.1 | 75 | 2.8 | 1.3 | 50 | 2.4 |

| 650 | 116 | 230 | 60 | 10 | 6.5 | 19.5 | 80 | 2.8 | 1.1 | 50 | 3 |

| 660 | 136 | 180 | 60 | 7 | 4.6 | 13.9 | 100 | 1.8 | 1.1 | 50 | 3.7 |

| 900 | 136 | 230 | 60 | 6 | 5.4 | 16.2 | 105 | 1.2 | 1.5 | 50 | 4.2 |

| 1000 | 136 | 260 | 70 | 5 | 5.0 | 15.0 | 120 | 0.9 | 1.5 | 50 | 4.7 |

| Spanning | 1800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 130 | 86 | 125 | 55 | 15 | 5.7 | 17.1 | 35 | 5 | 3.3 | 32 | 1.1 |

| 120 | 86 | 130 | 55 | 15 | 1.8 | 5.4 | 60 | 2.5 | 2.2 | 32 | 1.1 |

| 180 | 86 | 180 | 60 | 15 | 2.7 | 8.1 | 65 | 2 | 2.4 | 32 | 1.5 |

| 260 | 86 | 230 | 60 | 12 | 3.1 | 9.4 | 60 | 3 | 1.9 | 32 | 1.8 |

| 230 | 116 | 130 | 60 | 12 | 2.8 | 8.3 | 80 | 2 | 1.6 | 50 | 1.6 |

| 360 | 116 | 180 | 65 | 10 | 3.6 | 10.8 | 80 | 3.2 | 1.0 | 50 | 2.4 |

| 500 | 116 | 230 | 70 | 10 | 5.0 | 15.0 | 75 | 3 | 1.2 | 50 | 3 |

| 510 | 136 | 180 | 70 | 7 | 3.6 | 10.7 | 100 | 2 | 1.0 | 50 | 3.7 |

| 680 | 136 | 230 | 70 | 7 | 4.8 | 14.3 | 95 | 2 | 1.1 | 50 | 4.2 |

| Spanning | 2000V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 100 | 86 | 125 | 55 | 15 | 1.5 | 4.5 | 35 | 3.8 | 4.3 | 32 | 1.1 |

| 90 | 86 | 130 | 55 | 15 | 1.4 | 4.1 | 65 | 2.5 | 1.9 | 32 | 1.1 |

| 150 | 86 | 180 | 60 | 15 | 2.3 | 6.8 | 60 | 3.5 | 1.6 | 32 | 1.5 |

| 200 | 86 | 230 | 60 | 12 | 2.4 | 7.2 | 65 | 2 | 2.4 | 32 | 1.8 |

| 180 | 116 | 130 | 65 | 10 | 1.8 | 5.4 | 75 | 2.5 | 1.4 | 50 | 1.6 |

| 280 | 116 | 180 | 70 | 10 | 2.8 | 8.4 | 70 | 2 | 2.0 | 50 | 2.4 |

| 380 | 116 | 230 | 80 | 10 | 3.8 | 11.4 | 80 | 2 | 1.6 | 50 | 3 |

| 400 | 136 | 180 | 60 | 7 | 2.8 | 8.4 | 100 | 1.6 | 1.3 | 50 | 3.7 |

| 550 | 136 | 230 | 70 | 7 | 3.9 | 11.6 | 100 | 1.5 | 1.3 | 50 | 4.2 |

| 850 | 136 | 335 | 80 | 5 | 4.3 | 12.8 | 120 | 1.1 | 1.3 | 50 | 6.1 |

| Spanning | 2800V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 160 | 116 | 180 | 70 | 30 | 4.8 | 14.4 | 75 | 2.2 | 1.6 | 50 | 2.4 |

| 210 | 116 | 230 | 75 | 25 | 5.3 | 15.8 | 70 | 2.8 | 1.5 | 50 | 3 |

| 225 | 136 | 180 | 75 | 20 | 4.5 | 13.5 | 85 | 2 | 1.4 | 50 | 3.7 |

| 300 | 136 | 230 | 80 | 15 | 4.5 | 13.5 | 80 | 2.5 | 1.3 | 50 | 4.2 |

| Spanning | 4000V.GS | ||||||||||

| Cn(uF) | φD | H | ESL(nH) | dv/dt(V/μS) | Ip(KA) | Is(KA) | Irms(A) 50℃ | ESR (mΩ) @1KHz | Rth(K/W) | P(mm) | gewig |

| 70 | 116 | 180 | 70 | 50 | 3.5 | 10.5 | 70 | 3.5 | 1.2 | 50 | 2.4 |

| 95 | 116 | 230 | 75 | 40 | 3.8 | 11.4 | 70 | 3.6 | 1.1 | 50 | 3 |

| 100 | 136 | 180 | 75 | 35 | 3.5 | 10.5 | 85 | 3 | 0.9 | 50 | 3.7 |

| 135 | 136 | 230 | 80 | 30 | 4.1 | 12.2 | 80 | 3.5 | 0.9 | 50 | 4.2 |

CRE Polipropileenkragfilmkondensatorword gereeld in hoëspanningskragtoepassings gebruik as gevolg van hul hoë diëlektriese sterkte, lae volumetriese massa en uiters lae diëlektriese konstante (tanδ). CRE-kondensators ervaar ook lae verliese en, afhangende van die toepassingseise, is CRE-spesifieke kondensatoroplossings baie gewild onder kliënte regoor die wêreld.

CRE het 'n baie volwasse RD-span om hoë kwaliteit kragkondensatoroplossings vir kragomskakelingstelsels te lewer. Ons volg gewoonlik die beginsel van kliëntgerigte, detail-gefokusde vir Fabriek Goedkoop China kragelektroniese Filmkondensator. Ons hoop opreg om op die lange duur bevredigende interaksies met u te bewerkstellig. Ons sal u op hoogte hou van ons vordering en op hoogte bly van die bou van bestendige sakeverhoudings met u.

Fabriek China PP-filmkondensator, Meer as 26 jaar, Professionele maatskappye van oor die hele wêreld neem ons as hul langtermyn- en stabiele vennote. Ons handhaaf duursame sakeverhoudings met meer as 200 groothandelaars in Japan, Korea, VSA, VK, Duitsland, Kanada, Frankryk, Italië, Pole, Suid-Afrika, Ghana, Nigerië, ens.